Ecosense’s Green Hydrogen Lab is a portfolio of five independent, research-grade systems, each designed to address a specific part of the green hydrogen value chain. Institutions can adopt a single system or combine multiple systems to build a complete hydrogen facility based on their academic or research requirements.

Each product works on its own, offers full functionality, and includes integrated safety features.

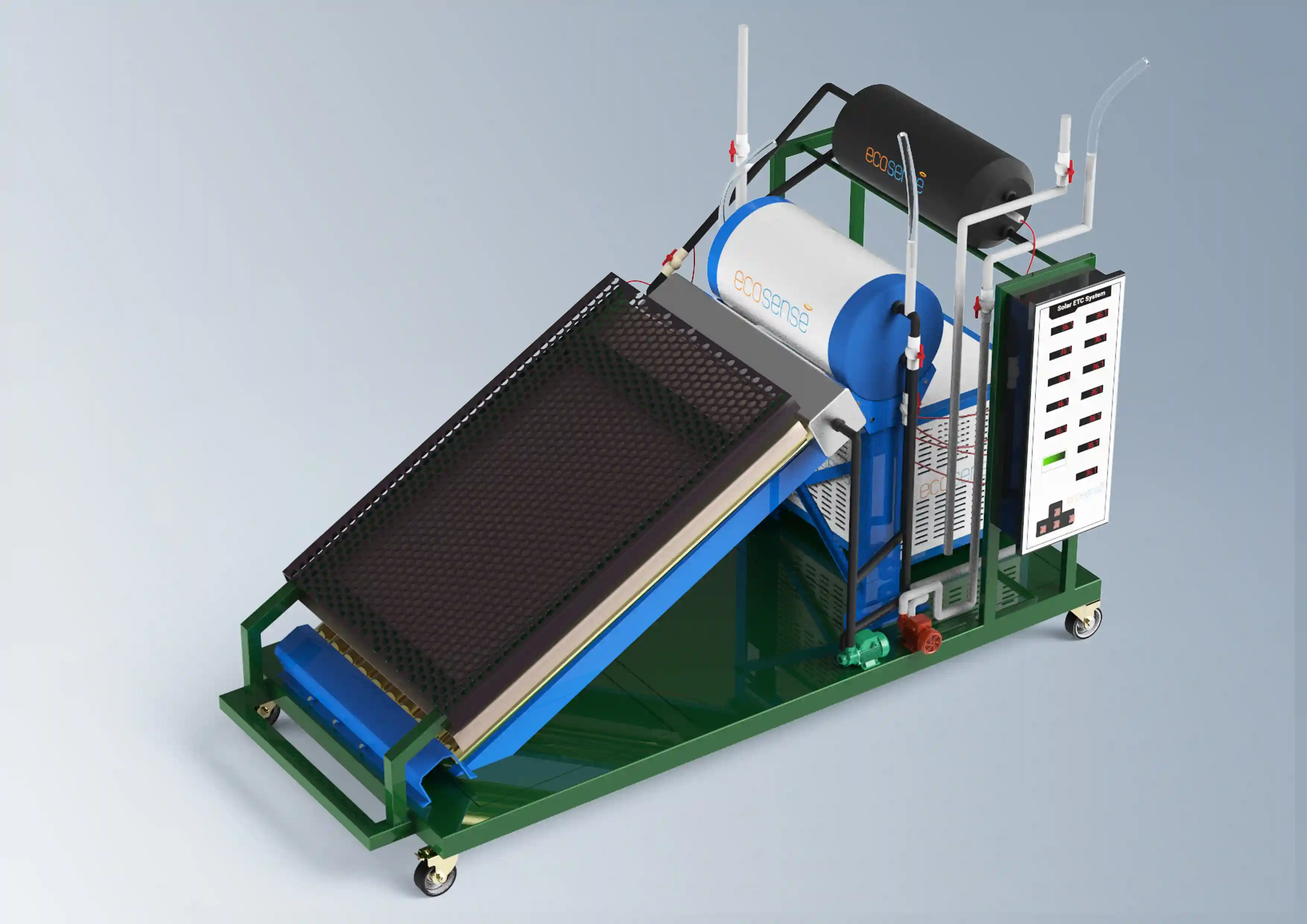

1. Green Hydrogen Generation & Storage System

This system demonstrates the production and storage of green hydrogen.

Users can choose the electrolyzer technology — PEM, AEM or Alkaline — to study production efficiency and chemistry.

Hydrogen produced is stored in certified Type-1, Type-2 or Type-3 cylinders with real-time leak detection, safety shut-offs, and controlled venting. It is ideal for fundamental learning in electrolysis, storage behavior, and hydrogen safety.

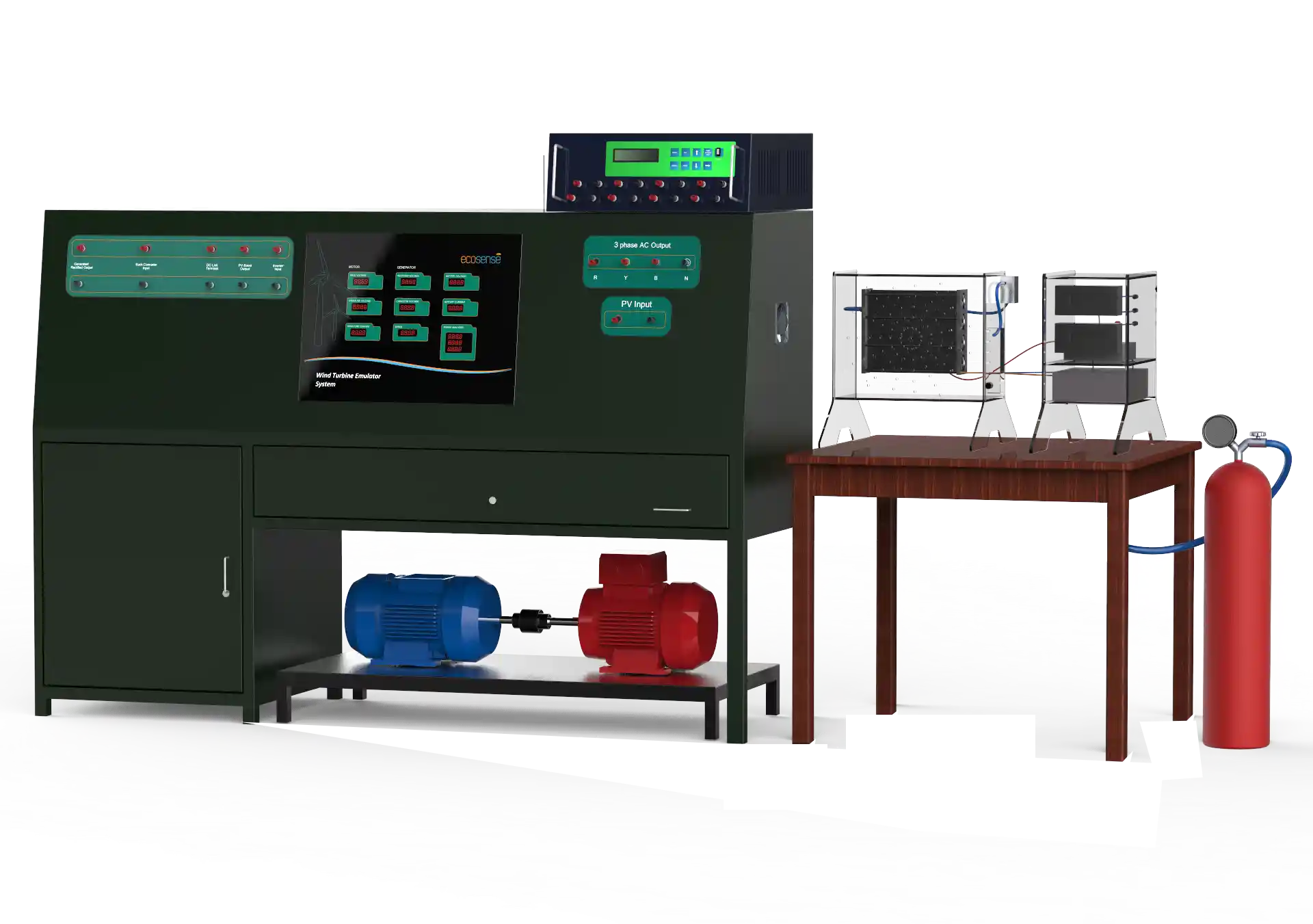

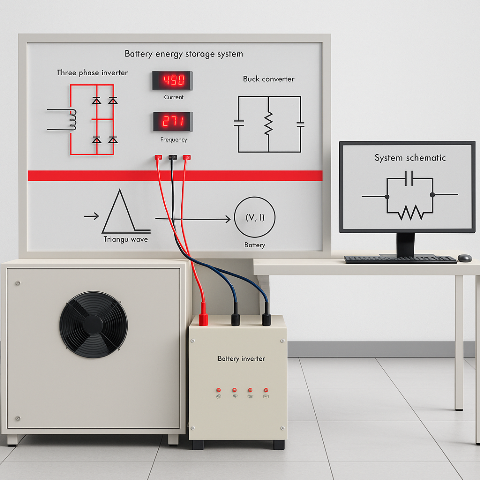

2. Green Hydrogen Generation, Storage & Utilization System

This platform builds on generation and storage by adding fuel-cell utilization. Hydrogen is fed to a PEM fuel cell to produce electricity and water, allowing students to analyse the complete energy cycle. Users can study fuel-cell V-I curves, load behaviour, electrical output, system efficiency, and performance variation under different operating conditions. The system is a full standalone hydrogen ecosystem in a single unit.

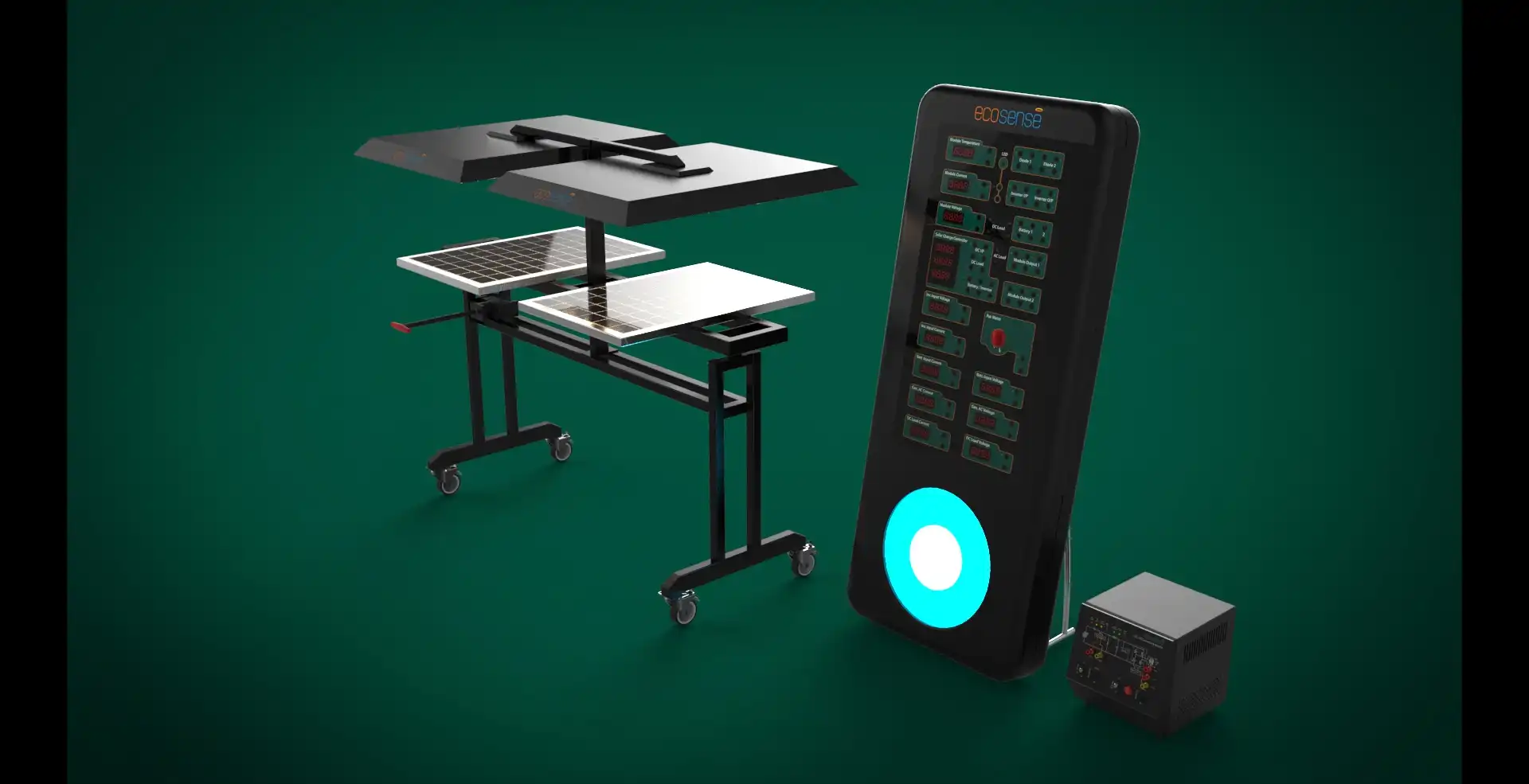

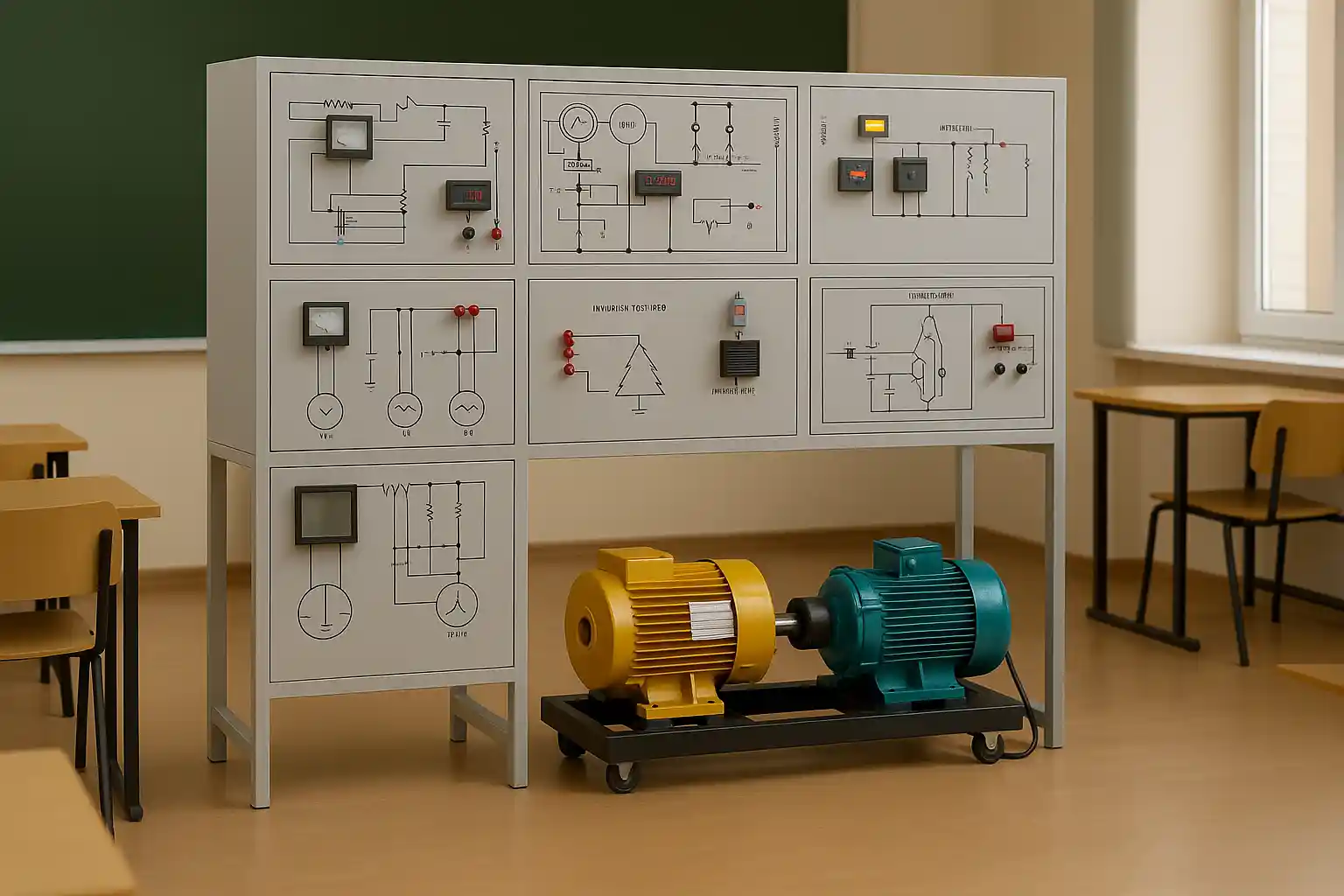

3. Green Hydrogen Microgrid

The Green Hydrogen Microgrid is a complete experimental and research system. It integrates renewable energy input, hydrogen generation, safe storage, and fuel-cell power generation into a working microgrid controlled by an energy management system.

Students and researchers can experiment with renewable intermittency, hydrogen buffering, peak shaving, and hybrid power flows. Along with this a student can explore control side of the microgrid and develop control algorithms using open source-editable code that comes with the system.

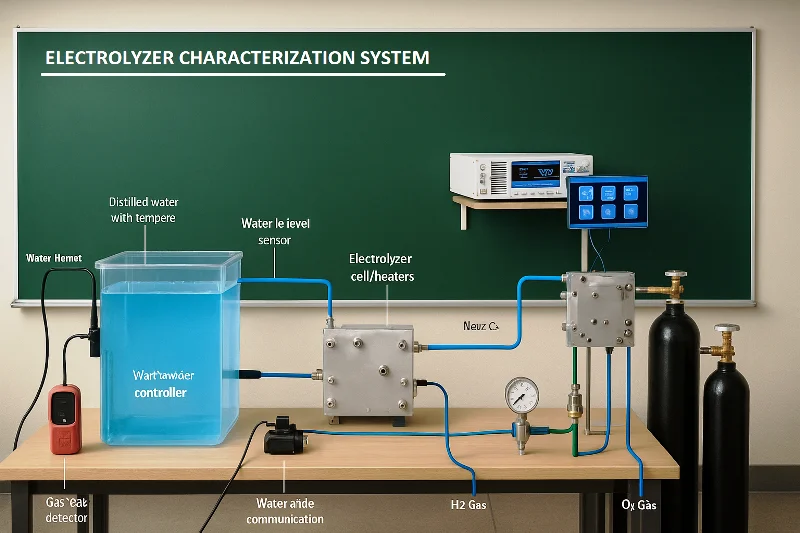

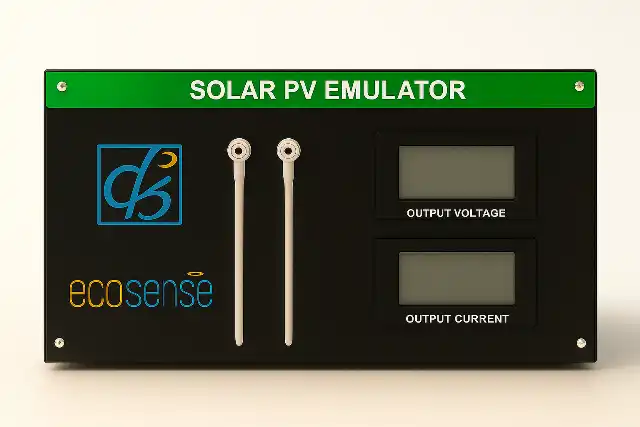

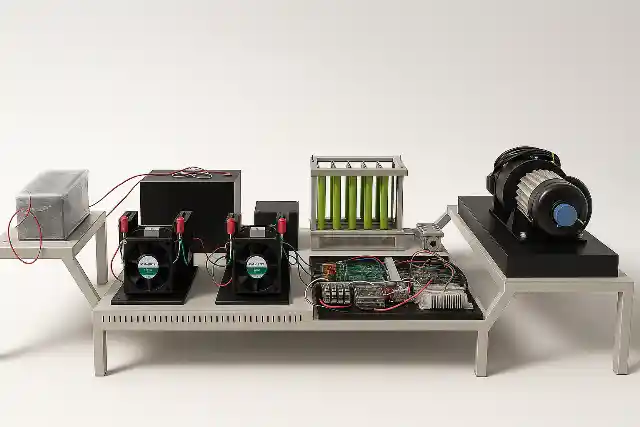

4. Electrolyzer Characterization System

This system is dedicated to scientific evaluation of electrolyzer performance. It allows controlled testing of different electrolyzer types under variable operating conditions, power input patterns, and water management settings. Users can extract detailed data such as efficiency curves, degradation behaviour, stack dynamics, response to transients, and power-to-gas ratios.

It is ideal for research, comparison studies, and product development activities.

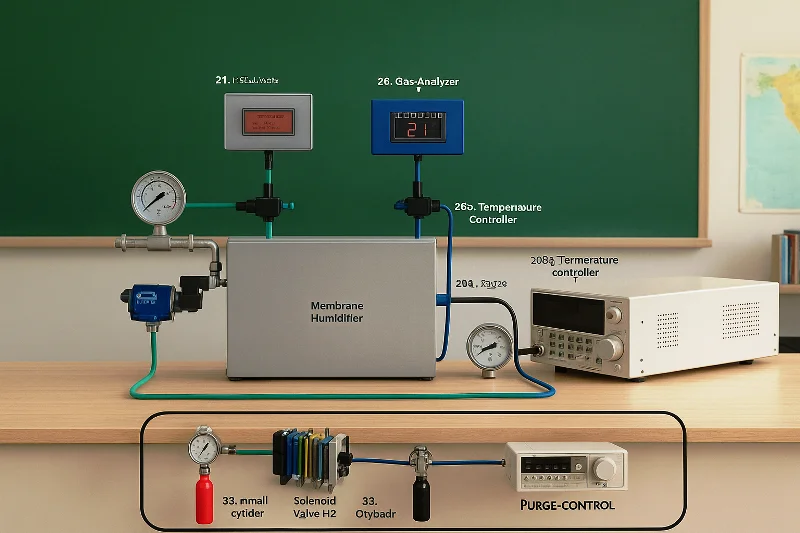

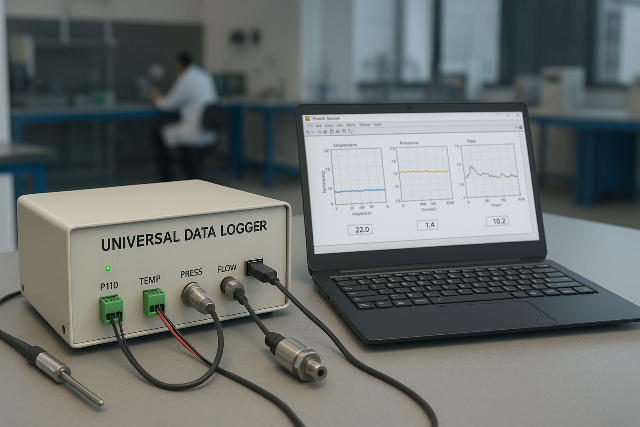

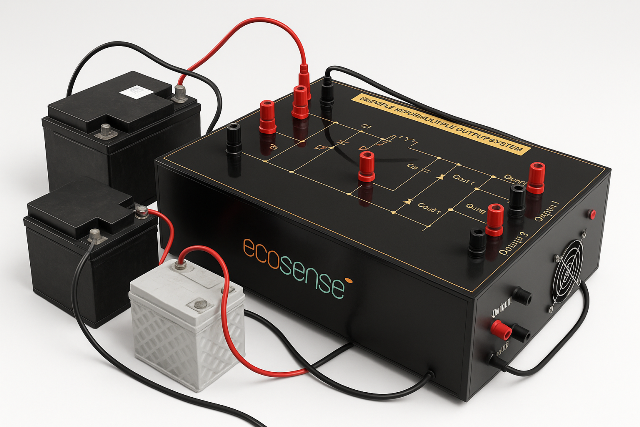

5. Fuel-Cell Characterization System

This standalone system focuses on fuel-cell stack performance. It supports experiments on polarization curves, thermal behaviour, gas flow rates, humidity influence, and conversion efficiency under controlled electrical loads. Students and researchers gain deep insight into fuel-cell operation and can compare performance across different setups and conditions.

It is widely used to teach the fundamentals of hydrogen-to-electricity conversion and for research, comparison studies, and product development activities..

Choose One System or Build the Full Spectrum

All five systems are independent, complete and deployable without the others.Institutions can start with any product based on curriculum focus — from basic electrolysis learning to advanced microgrid experimentation. Over time, multiple systems can be combined to create a full hydrogen learning ecosystem without changing the original installations.