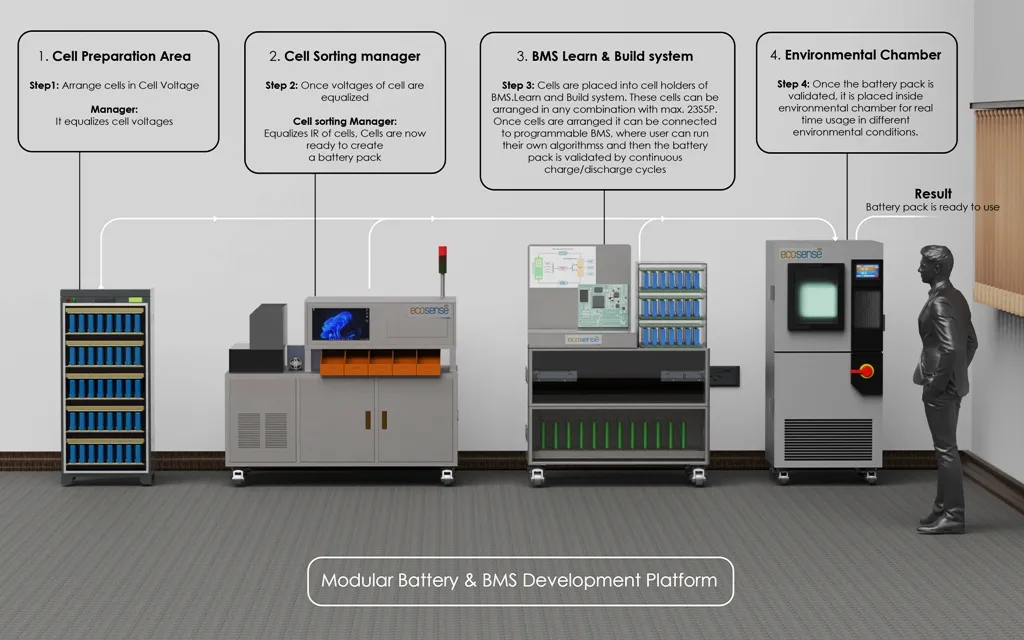

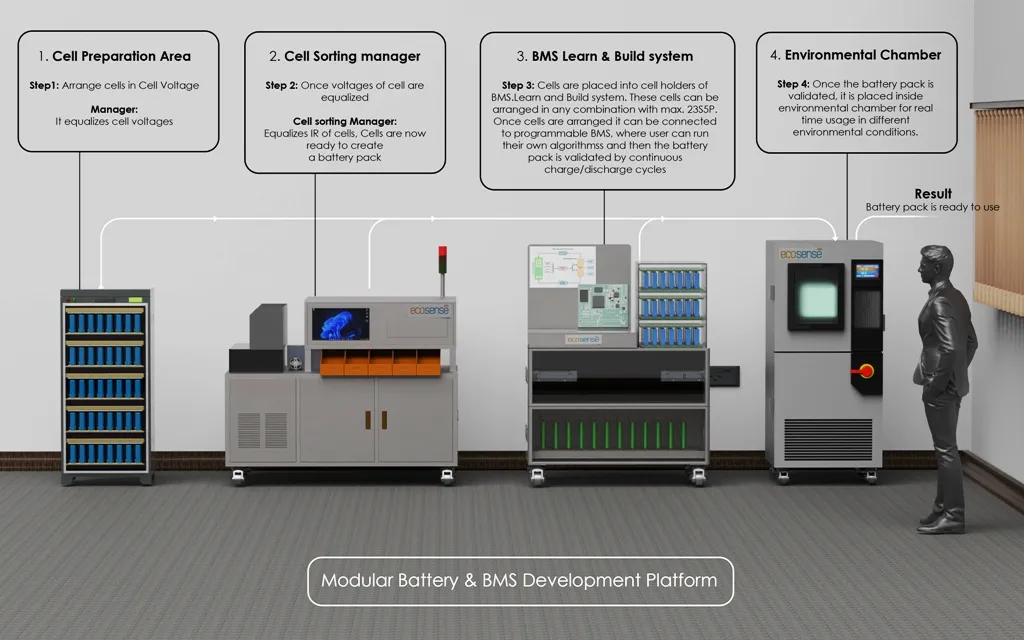

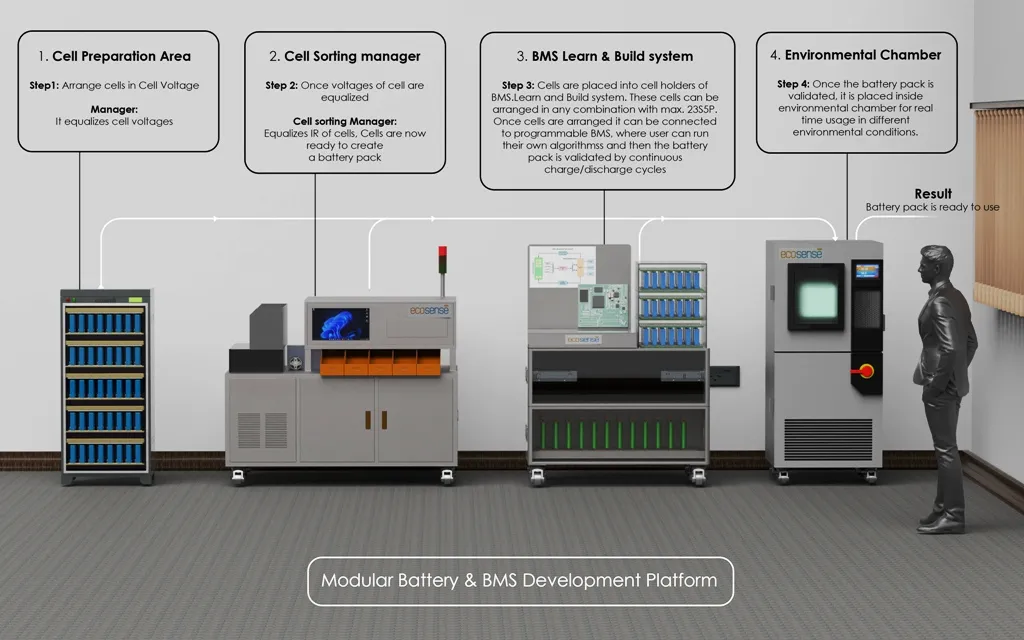

Modular Battery & BMS Development Platform

The future of electric mobility and energy storage depends on intelligent battery systems. At the heart of every high-performance battery pack lies a robust Battery Management System (BMS). The Modular Battery & BMS Development Platform bridges the gap between theoretical learning and real-world battery engineering. Designed for universities, R&D labs, and battery developers, this platform enables complete battery lifecycle development — from cell preparation and sorting to pack assembly, BMS algorithm design, validation, and environmental testing. It is not just a training kit. It is a full-scale battery research and validation ecosystem.