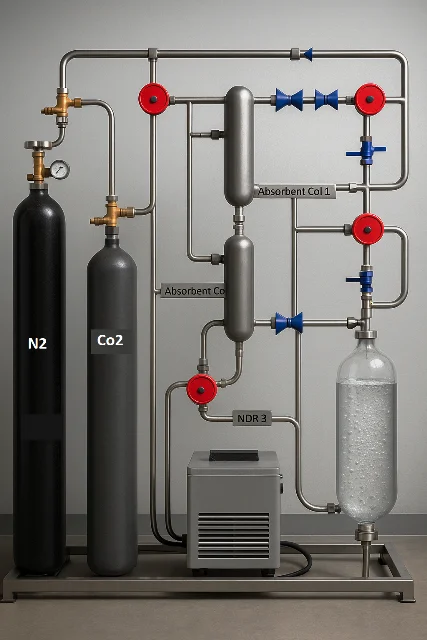

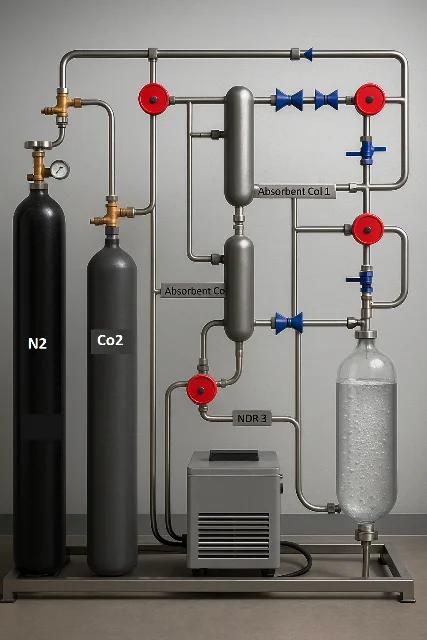

Integrated Platform for Carbon Capture and Utilization

The Integrated Platform for Carbon Capture and Utilization is a comprehensive, hands-on educational system designed to bring real-world carbon capture utilization and storage processes into academic laboratories. Developed for engineering and science institutions, this lab-scale setup enables students and researchers to study the complete CCUS workflow—from simulated carbon emissions and selective adsorption to controlled desorption and final mineralization into stable compounds such as CaCO₃. By combining precision gas handling, advanced sensing, and PID-based control, the platform enables practical understanding of carbon capture and storage under controlled and repeatable laboratory conditions. Its IoT-enabled data acquisition system supports both foundational teaching and advanced experimental research.