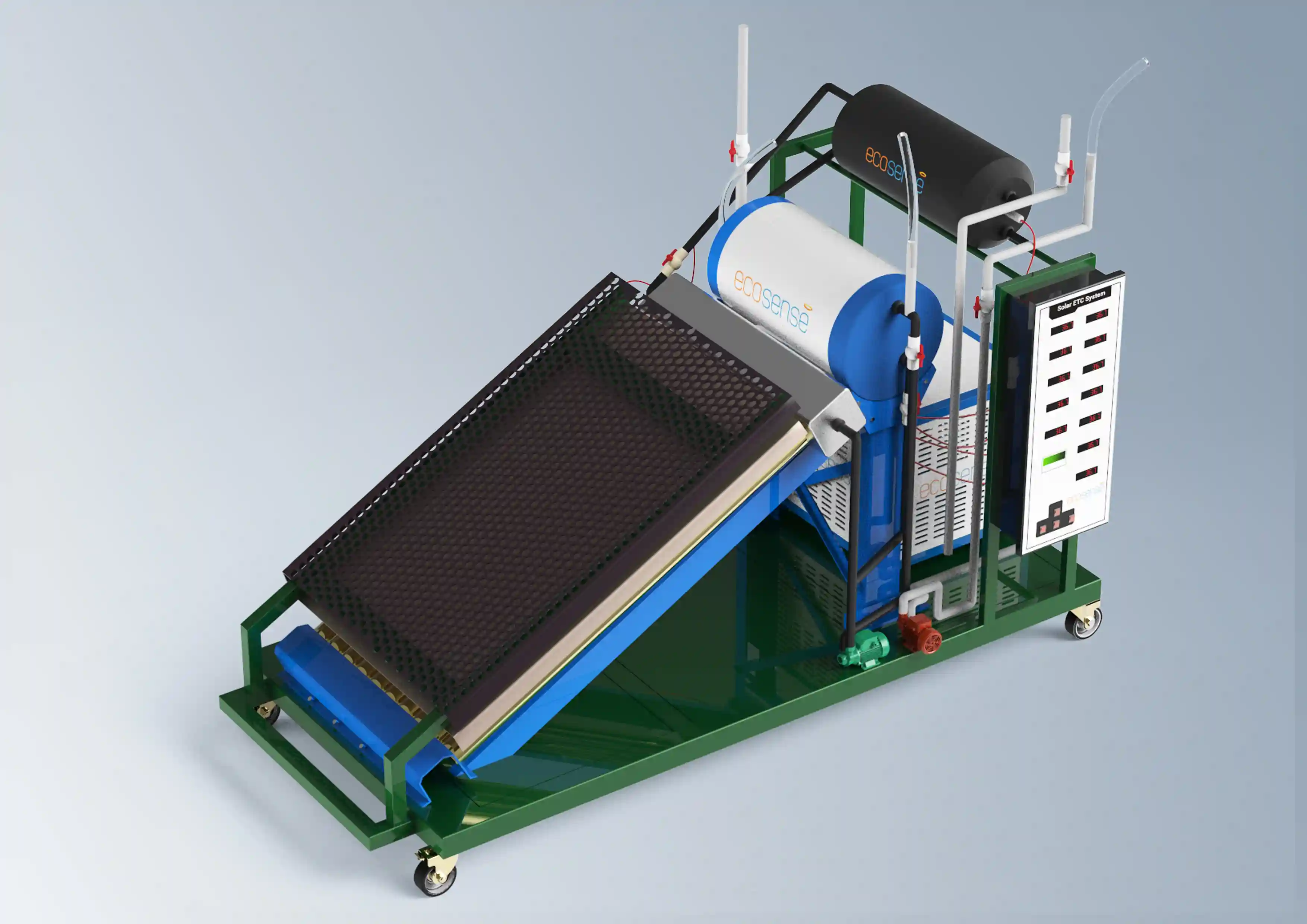

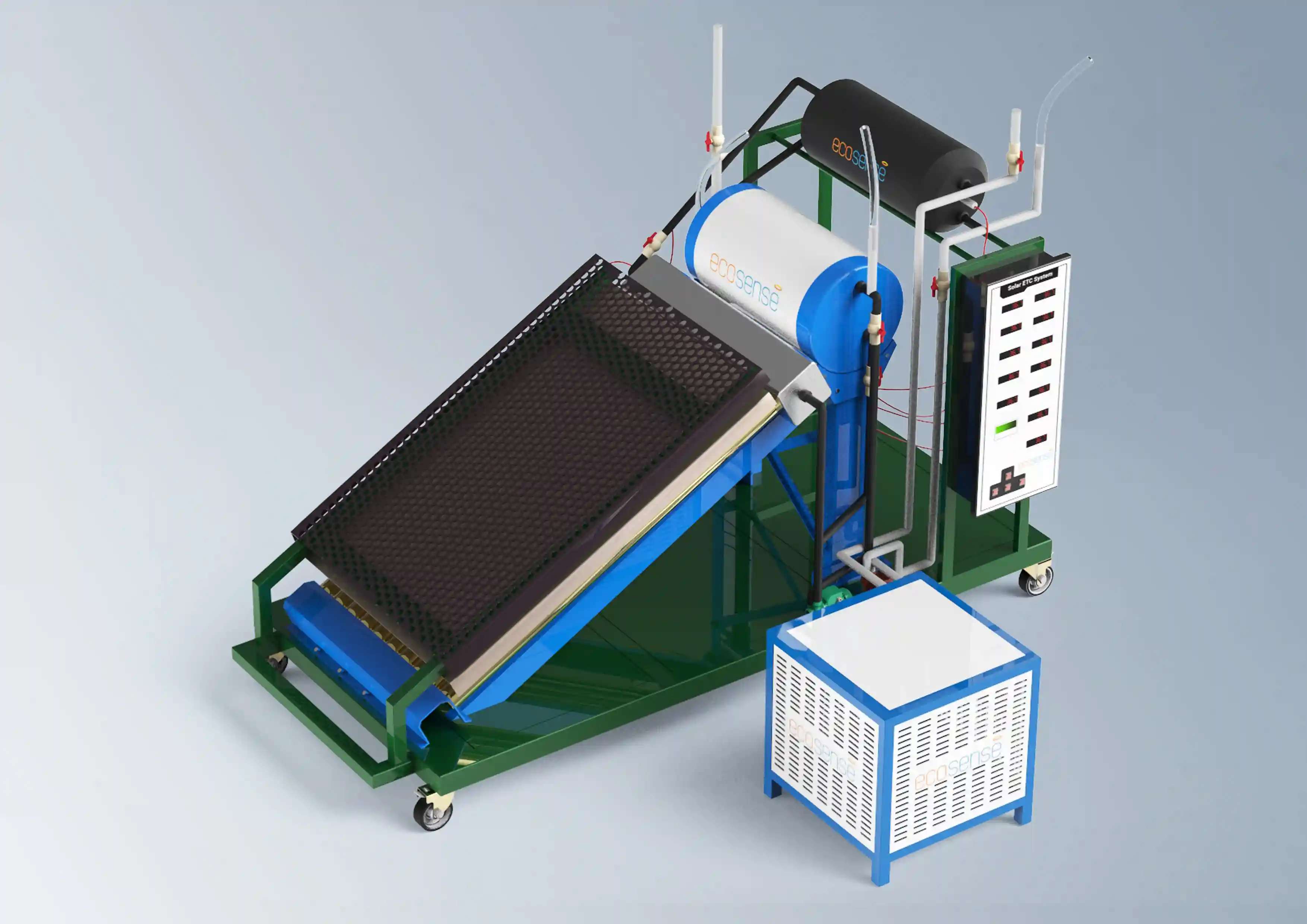

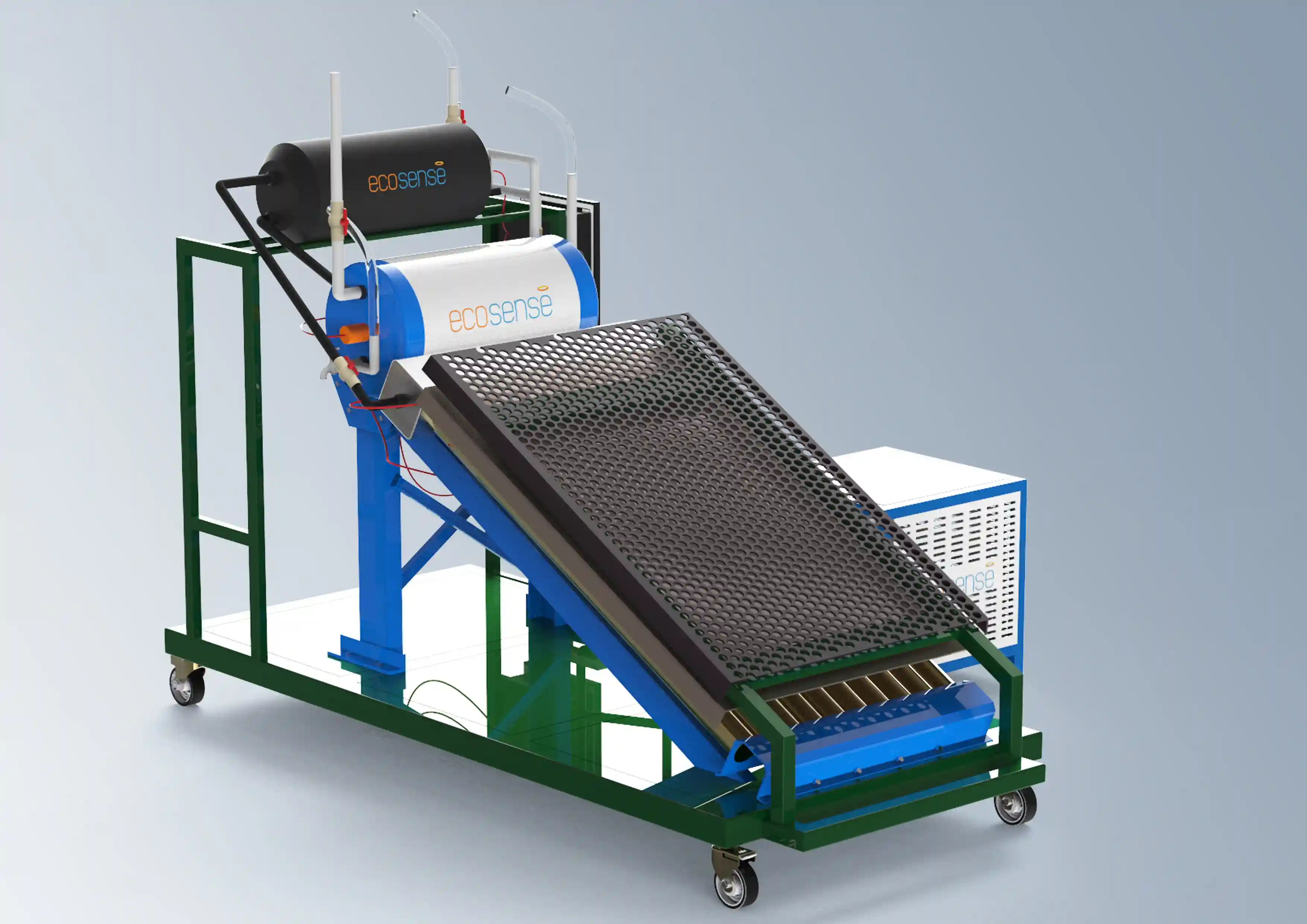

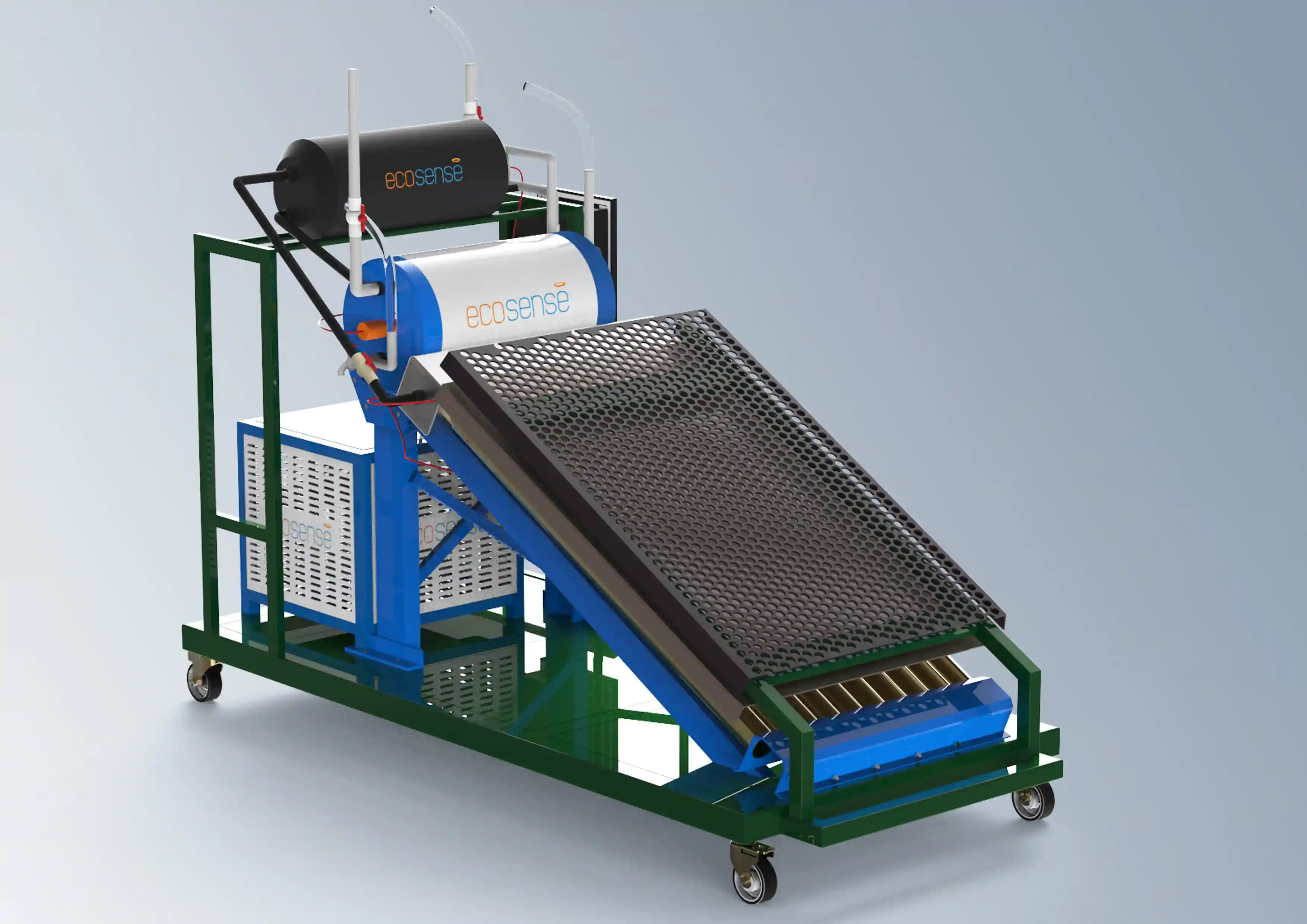

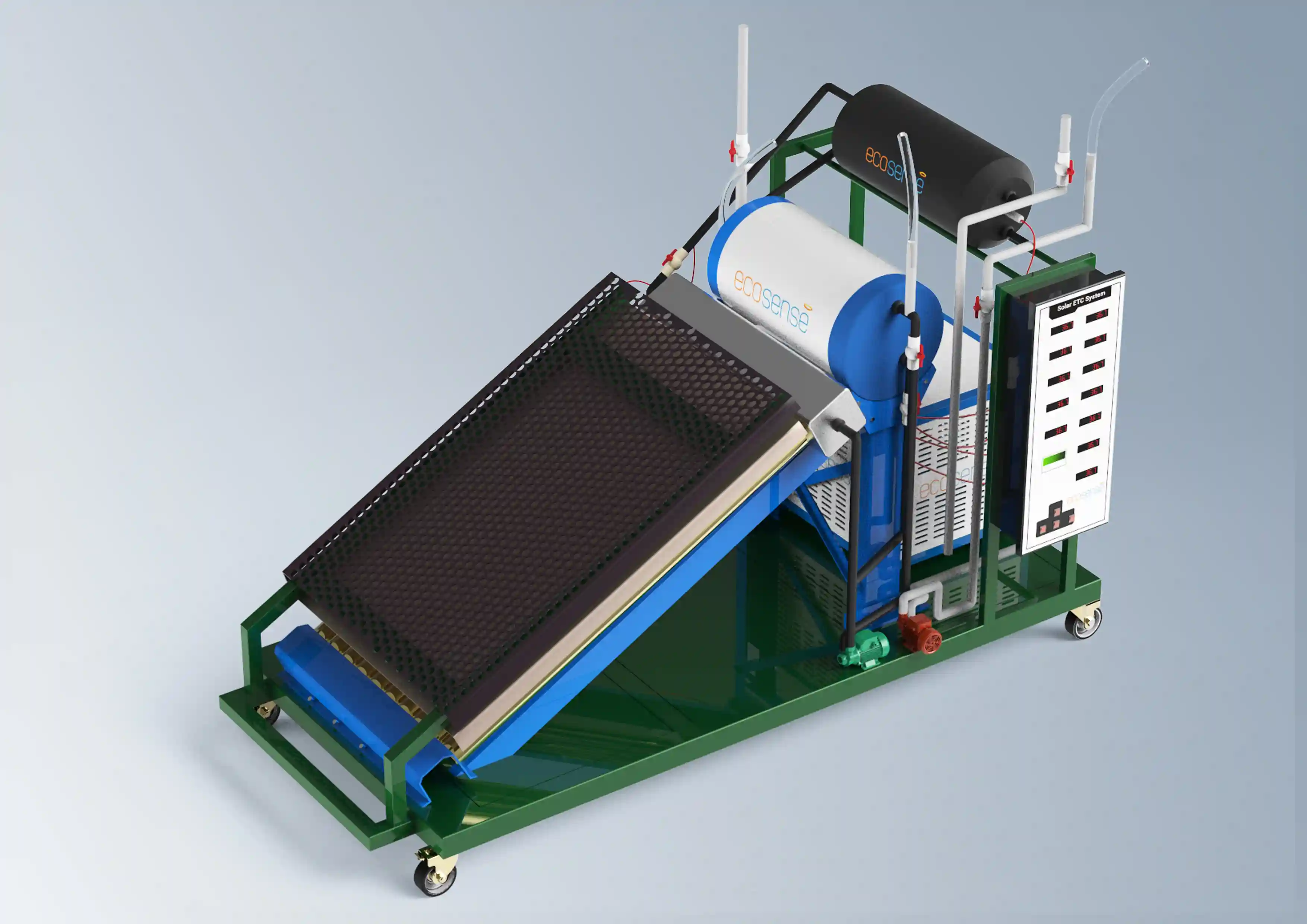

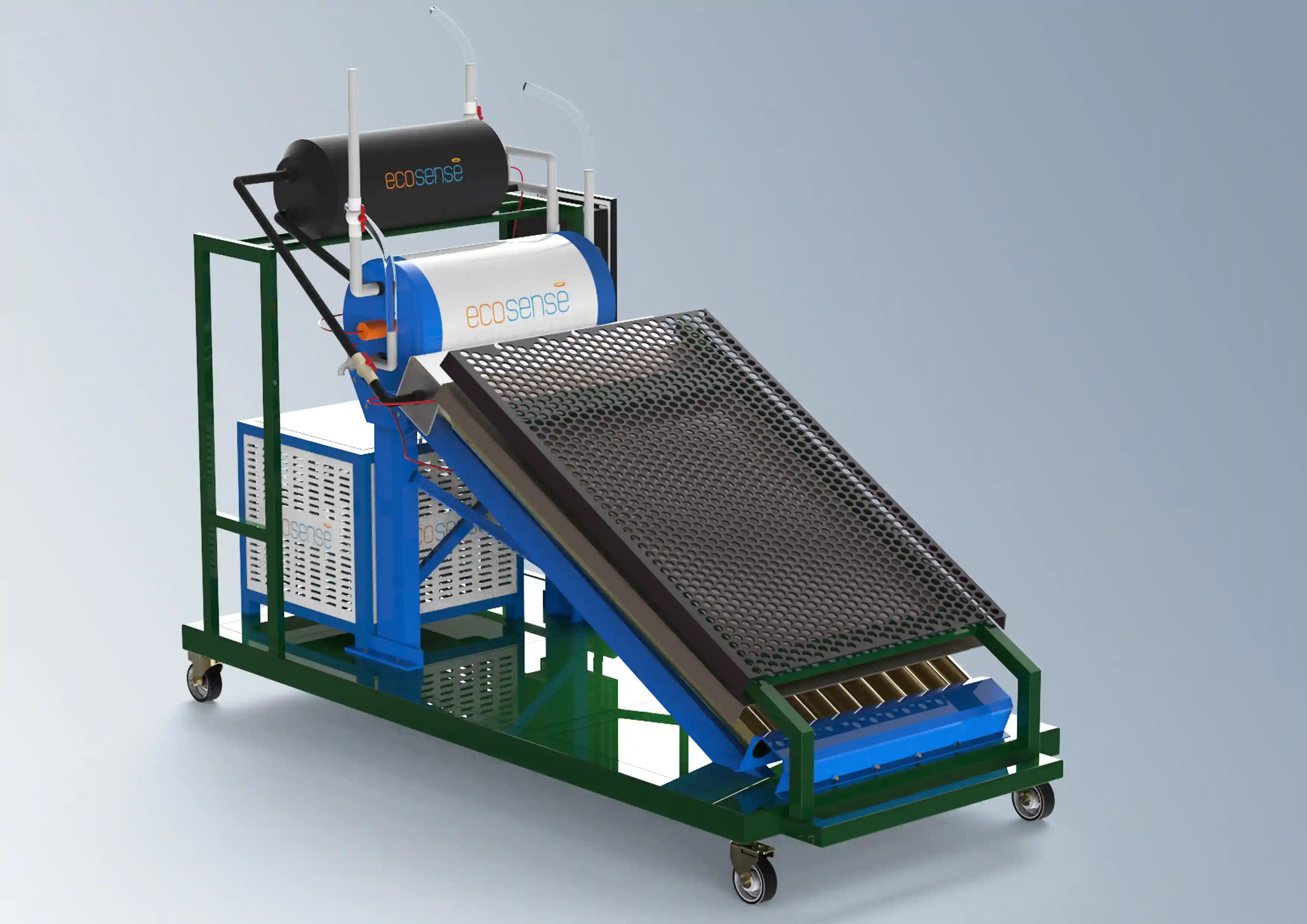

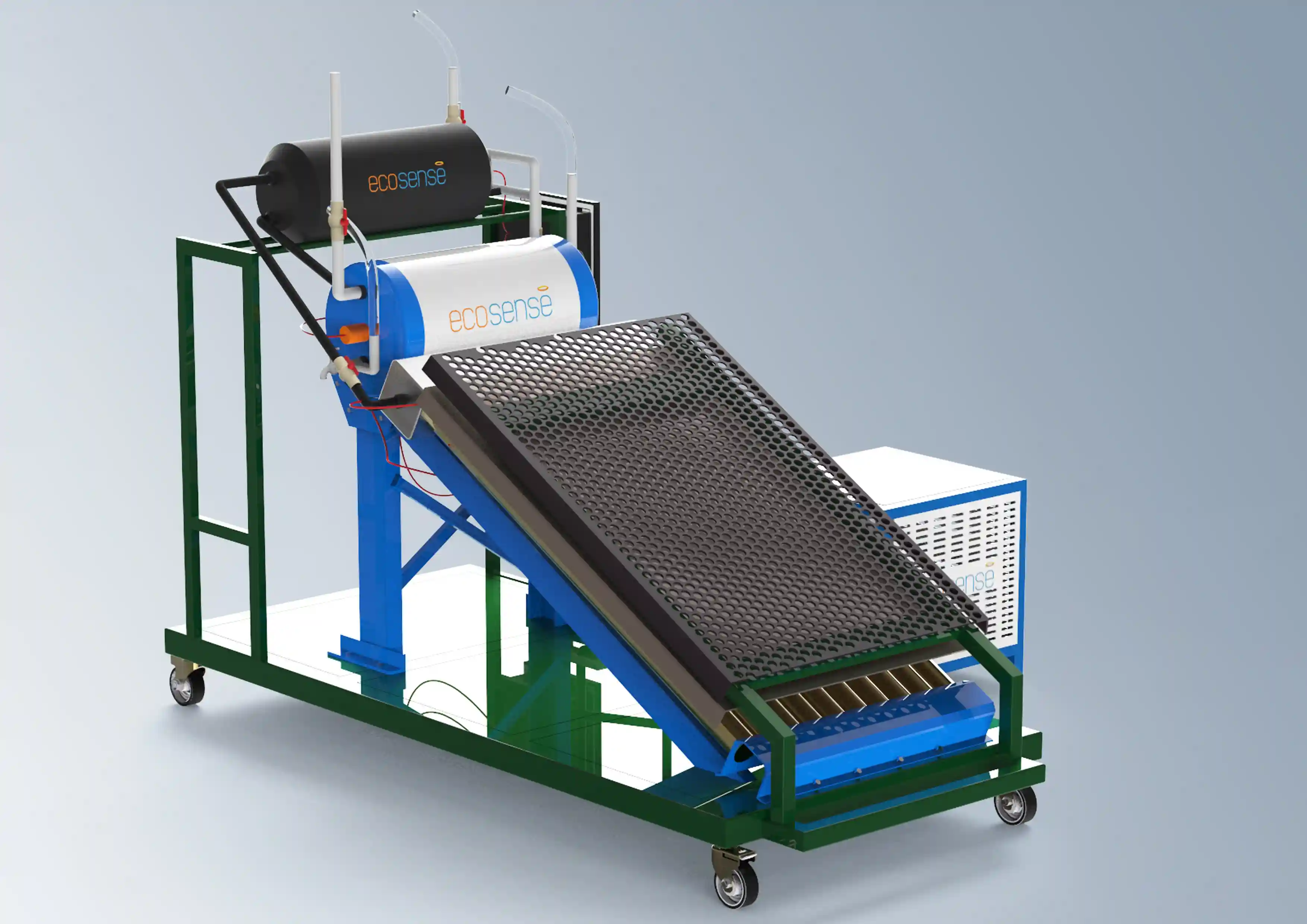

ETC Characterization System

The ETC Characterization System is a compact, closed-loop Evacuated Tube Collector (ETC) setup designed for in-depth thermal analysis of various fluids. Utilizing an artificial sunlight source, this system enables controlled, indoor experimentation independent of natural climate conditions. Ideal for educational institutions, it also serves as a robust platform for advanced research on heat transfer, system efficiency, and the performance of different working fluids, including nanofluids.