Molten Salt Storage: Thermal Tech, Cost Savings & Future

As solar power expands across India’s renewable landscape, the challenge lies in storing heat energy efficiently for use during non-solar hours. Molten salt thermal storage technology addresses this challenge with its ability to store vast amounts of thermal energy at high temperatures and release it on demand. Integrated with Concentrated Solar Power (CSP) systems, molten salt storage ensures consistent, dispatchable power generation — a key step toward achieving India’s 2070 net-zero vision.

What is Molten Salt Storage?

Molten Salt Energy Storage (MSES) is a thermal energy storage (TES) system that uses nitrate-based salts, typically a eutectic mixture of 60% sodium nitrate (NaNO₃) and 40% potassium nitrate (KNO₃), known as Solar Salt.

These salts remain in a liquid state within a temperature window of 290°C to 565°C, allowing them to store and transfer heat efficiently without degradation.

In CSP systems, molten salt acts as both a heat transfer fluid (HTF) and a thermal reservoir, storing solar heat collected by concentrators and later using it to produce superheated steam for electricity generation.

How Molten Salt Storage Works?

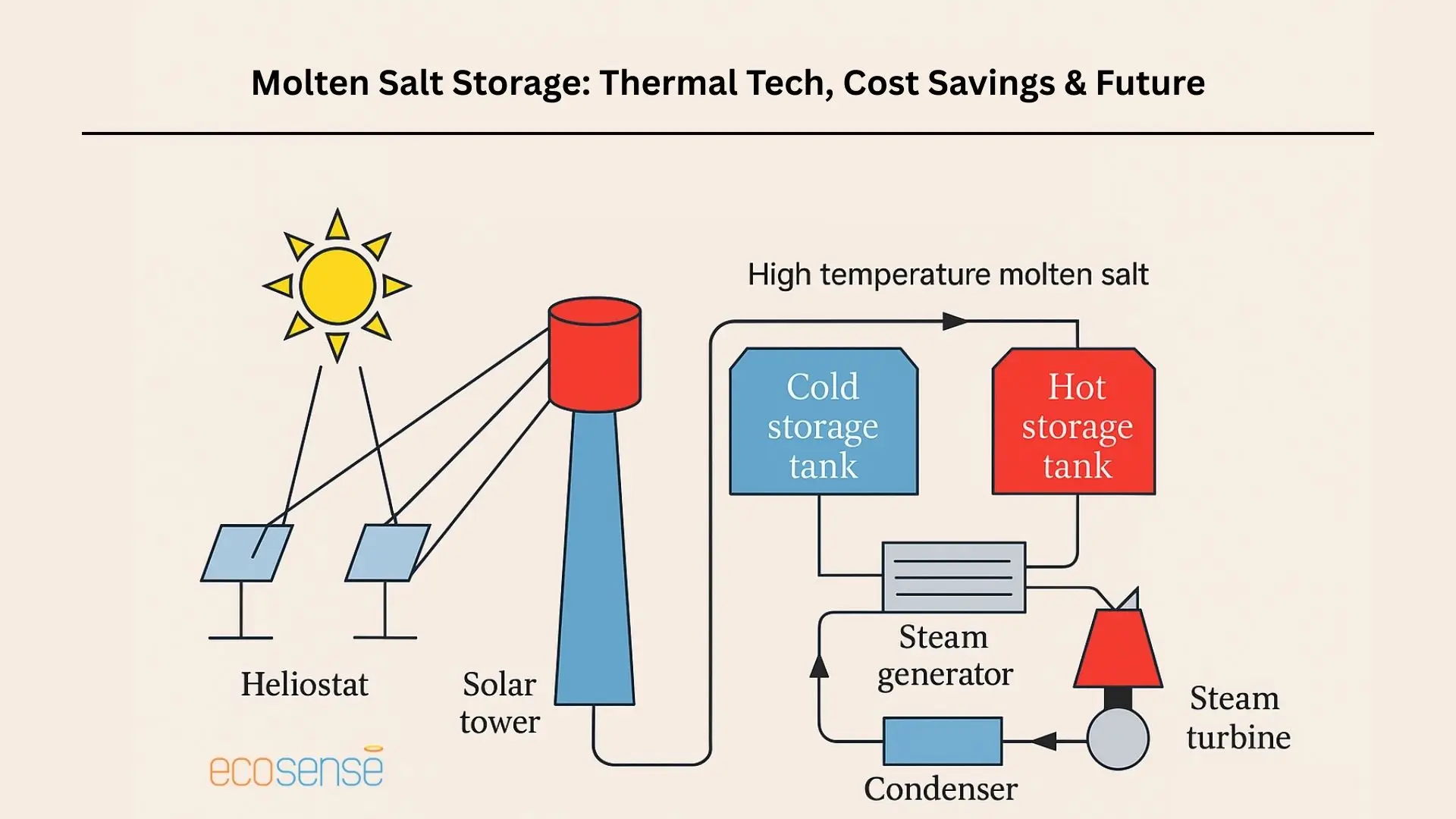

Molten salt storage typically uses a two-tank indirect system, comprising a Cold Tank (≈290°C) and a Hot Tank (≈565°C) connected through a heat exchanger network.

Here is how the system operates step-by-step:

- Solar Energy Collection: A parabolic trough, solar tower, or linear Fresnel collector focuses sunlight onto a receiver. The concentrated rays heat a heat transfer fluid (HTF), usually synthetic oil or molten salt itself.

- Heat Exchange: The hot HTF passes through a shell-and-tube heat exchanger, transferring thermal energy to the molten salt in the hot tank.

- Thermal Storage: The hot tank, insulated with ceramic fiber or mineral wool and lined with stainless steel (SS 316L), stores the molten salt at high temperature and pressure.

- Power Generation: When electricity is needed, molten salt flows through another heat exchanger that generates superheated steam (≈540°C, 100 bar) to drive a Rankine cycle turbine.

- Recirculation: After energy extraction, the cooler molten salt returns to the cold tank, ready for reheating — ensuring a continuous, closed-loop operation.

Fig. Molten Salt energy Storage

The Thermal Technology Behind Molten Salt Storage

Molten salt systems operate on the principle of sensible heat storage, where thermal energy is stored by raising the temperature of the molten medium.

Key technical aspects include:

- Salt Composition: Binary mixtures of NaNO₃–KNO₃ or ternary salts with Ca(NO₃)₂ for lower melting points.

- Operating Temperature Range: Typically 290°C (cold) to 565°C (hot), with some advanced salts reaching 600°C+.

- Tank Material: Austenitic stainless steel (SS 316L or Inconel 625) ensures corrosion resistance.

- Heat Loss Prevention: Multi-layer insulation limits losses to less than 1% per day.

- Pump and Flow Control: Centrifugal pumps designed for high-viscosity fluids maintain flow rates of 10–20 m³/h, ensuring efficient heat transfer.

- Efficiency: Overall round-trip efficiency is typically 90–95%, depending on tank insulation and ambient conditions.

Cost Savings: Economic Edge Over Conventional Storage

Molten salt storage provides a cost-effective solution for long-duration energy storage, especially for utility-scale solar projects.

Compared to lithium-ion batteries or mechanical systems, the advantages include:

- Lower Levelized Cost of Storage (LCOS): Around ₹4–6 per kWh-thermal, significantly cheaper than chemical batteries.

- High Energy Density: Enables 10–15 hours of full-load energy dispatch.

- Long Operational Life: More than 30 years with minimal capacity loss.

- Local Availability: India has domestic sources of nitrate salts, reducing import dependency.

- Reduced CapEx per kWh: Especially beneficial for CSP plants above 50 MW capacity.

For India’s economics, this technology supports grid stability, reduces diesel-based backup, and complements National Solar Mission goals through reliable thermal storage.

How Ecosense is Advancing Molten Salt Storage Innovation?

Ecosense Sustainable Solutions develops Solar Thermal Energy Storage System integrated with Solar FPC/ Solar ETC/ Solar PTC or CSP system that allow academic and R&D institutions to simulate molten salt storage and analyze thermal performance parameters such as:

- Heat transfer coefficient variation with flow rate

- Temperature distribution within the storage medium

- Thermal efficiency and exergy analysis

- Salt degradation studies under cyclic heating

Our Solar Thermal Lab Systems are built for real-time experimentation, equipping engineers to design and optimize future CSP-integrated storage systems for industrial and utility applications.

Shaping the Solar Future: Applications and Transformative Impact

Molten salt storage is rapidly transforming India’s renewable infrastructure, particularly in solar-rich regions like Rajasthan, Gujarat, and Ladakh. Key applications include:

- Concentrated Solar Power (CSP) plants — dispatchable energy for 24×7 generation

- Industrial heating — for metallurgy, chemical processing, and desalination

- Green hydrogen generation — thermal coupling with electrolyzers for efficient hydrogen production

- Hybrid renewable grids — integrating wind and solar with thermal buffering

- District heating and cooling — especially in smart city infrastructure

These applications highlight how molten salt technology bridges the gap between solar energy availability and grid demand, supporting India’s march toward 500 GW of renewable capacity by 2030.

Conclusion

Molten salt thermal storage is more than just a storage medium—it’s the backbone of next-generation solar power systems. By combining thermal stability, scalability, and low lifecycle cost, it enables renewable energy to be as reliable as conventional power. Ecosense continues to champion this evolution, empowering engineers, and researchers to drive innovation in sustainable solar thermal technologies.