Connecting Solar Panels in Series Vs Parallel

Most people working with solar panels already understand series and parallel connections. That part is not the challenge. The real decision begins when the panels need to be connected to something—an inverter, a charge controller, or a battery bank. At that stage, wiring is no longer about theory. It becomes about matching voltage and current ratings correctly. The choice between series and parallel depends on what the downstream equipment can accept, how much voltage it requires to operate efficiently, and how much current it can safely handle. Get that match right, and the system runs smoothly. Get it wrong, and performance, safety, and reliability all suffer.

What Does “Series Connection” Mean in a Solar PV System?

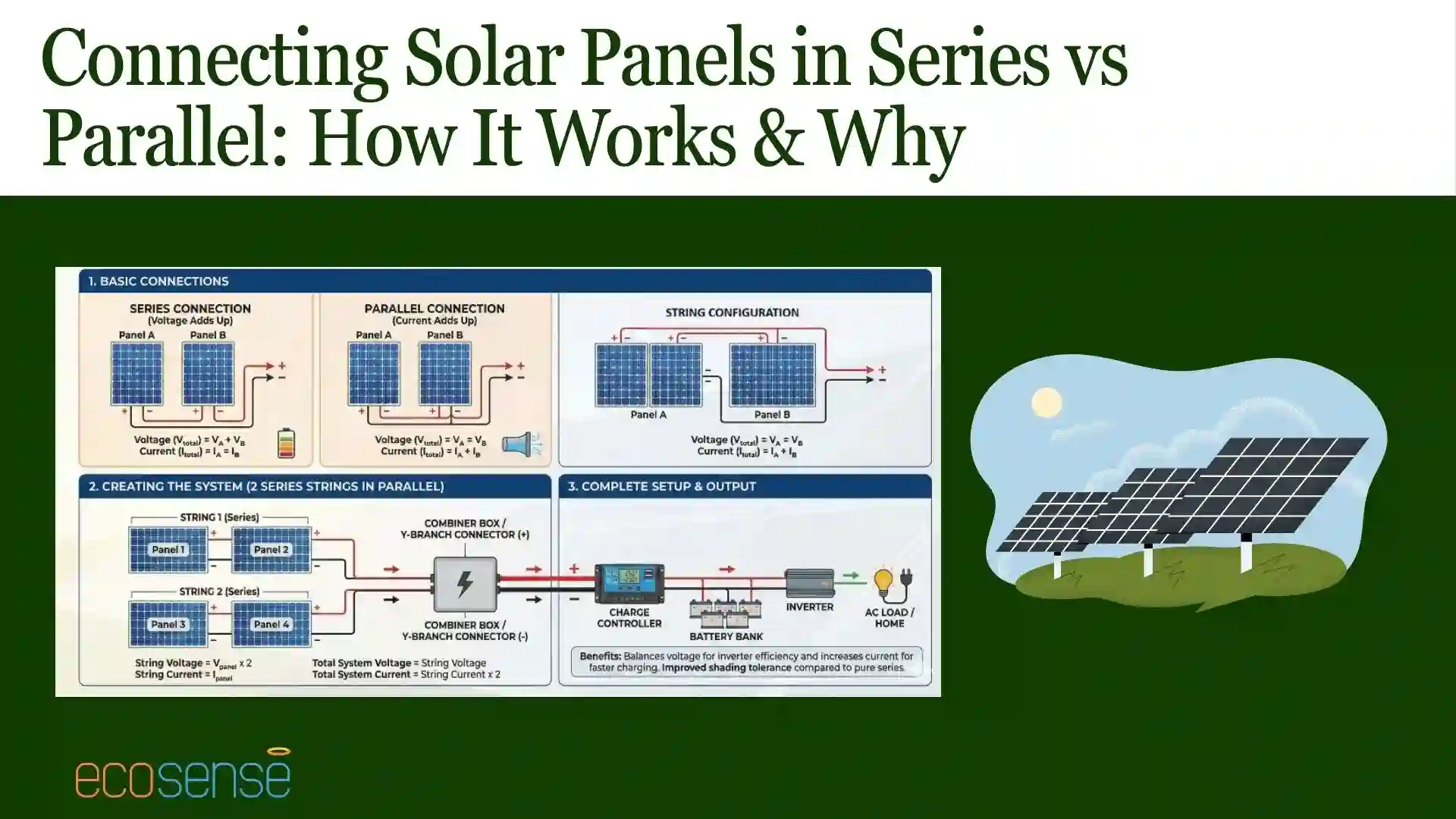

A series connection links panels one after another. Series connection means connecting positive terminal of one panel to the negative terminal of the next. When panels are connected in this manner, the voltages add up while current remains the same. For example, when 4 panels of 10V and 2A are connected in series the resultant voltage becomes 40V while resultant current is still 2 A. The resultant current and voltages are measured between positive terminal of first panel and negative terminal of the last one. This method of connecting solar in series is used when the system needs higher DC voltage and low current to operate efficiently.

Understanding Series vs Parallel Connections in Solar Systems

Series and parallel wiring solve different problems. Series wiring raises voltage. Parallel wiring raises current. That single difference drives most design decisions. High-voltage systems benefit from series strings because lower current means lower cable losses. That explains why solar panels are connected in series in grid-tied systems. Parallel wiring keeps voltage fixed and add current instead. It is common in battery-based setups where voltage limits are strict. Neither approach is “better” on its own. Each matches a specific operating need.

How Series Connection Changes the Electrical Output of Solar Panels

When panels are connected in series, their voltages add up. Four identical panels produce four times the voltage of one panel, but the same current. Higher voltage reduces resistive losses in cables and improves inverter efficiency. This efficiency gain is a key reason why solar cells are connected in series. The downside is sensitivity. If one panel underperforms, the entire string is affected. Bypass diodes help, but the weakest panel still sets the limit. Series wiring rewards uniform conditions and careful layout.

When to Use Series, Parallel or Series-Parallel Wiring

Series wiring works well when panels receive similar sunlight and the inverter requires higher voltage. Parallel wiring suits systems where shading varies or where batteries fix the system voltage. Many real installations fall somewhere in between. That’s where series-parallel wiring comes in. Panels are grouped into series strings, then those strings are connected in parallel. This balances voltage, current, and reliability. It also makes future expansion easier, which is why larger systems rarely rely on a single wiring method.

How to Set Up Your System in Parallel?

In a parallel configuration, all positive terminals connect together, and all negative terminals connect together. The system voltage stays the same as one panel. Current increases as more panels are added. This approach is common in off-grid and battery-based systems. Parallel wiring handles partial shading better because one weak panel does not pull down the rest. The trade-off is higher current, which demands thicker cables and proper protection.

Fig.1 Parallel connection of Solar Panels

How to Set Up Your System in Series?

In a series setup, panels are connected in a chain until the required voltage is reached. This layout is typical in grid-connected systems and clearly shows why solar panels are connected in series. Lower current simplifies cabling and improves efficiency over longer distances. Designers must account for temperature effects, since panel voltage rises in cold conditions. Ignoring this can push string voltage beyond inverter limits.

Fig.2 Series connection of Solar Panels

How to Set Up Your System in Series-Parallel?

Series-parallel wiring starts with series strings. Those strings are then connected in parallel. This allows voltage and current to be tuned independently. It is widely used in commercial rooftops and institutional projects. Series-parallel layouts improve fault tolerance, reduce mismatch losses, and simplify maintenance. The system continues operating even if one string underperforms.

Fig.3 Series & Parallel combination connection of Solar Panels

Conclusion

Solar wiring is not an afterthought. It shapes how the entire system behaves. Connecting solar cells in series improves efficiency and suits high-voltage designs. Parallel wiring offers flexibility where voltage must stay low. Series-parallel layouts balance both. The right choice depends on site conditions, equipment limits, and future plans. Good wiring design is invisible when done right—and expensive when done wrong.