How Thermal Management Impacts EV Battery Life

How Thermal Management Impacts EV Battery Life

When you buy an electric vehicle, you usually check its range, charging time, or battery capacity. But here’s a little secret: what really decides how long that EV lasts isn’t just the battery chemistry—it’s temperature.

Batteries are like people. They perform their best when they’re not too hot, not too cold, but just right. Push them outside their comfort zone and they get sluggish, lose efficiency, and wear out faster. That’s why every modern EV relies on a Battery Thermal Management System (BTMS)—the hidden system that keeps those batteries alive and well.

For students and educators stepping into the world of EV engineering, learning how thermal management affects battery life is no longer optional—it’s essential.

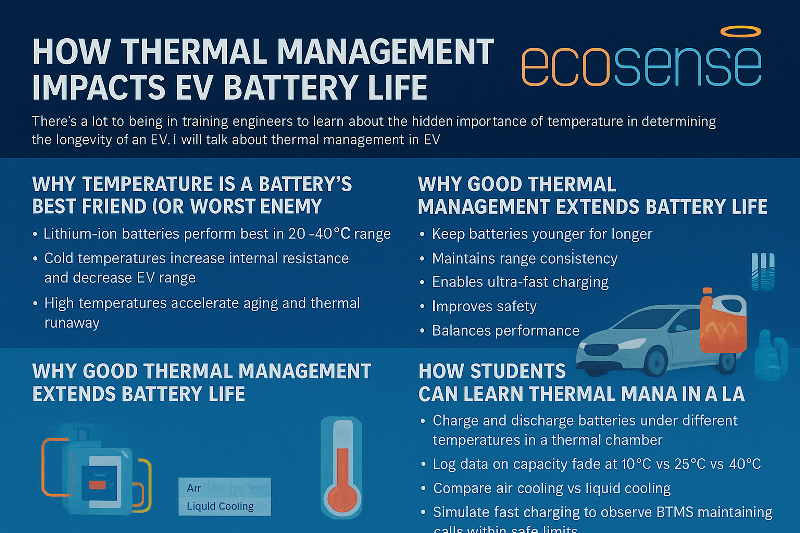

Why Temperature Is a Battery’s Best Friend (or Worst Enemy)

Think of lithium-ion batteries as athletes. They love competing in the sweet spot of 20–40°C. Within this range, their energy flows smoothly, charging is fast, and they can go the distance.

But change the conditions and things fall apart:

- In the cold, batteries act stiff. Internal resistance shoots up, charging slows down, and your EV’s range drops—just like you struggling to get out of bed on a freezing morning.

- In the heat, batteries age too quickly. Chemical reactions inside them speed up, and over time the cells lose their ability to hold charge. Worse still, extreme heat can trigger thermal runaway, the nightmare scenario every engineer wants to avoid.

- Uneven temperatures across cells create imbalance. Some cells retire early, dragging down the whole pack—like a team where one tired player slows everyone else.

The lesson is clear: temperature is destiny for EV batteries.

Meet the Silent Guardian: Battery Thermal Management System (BTMS)

A BTMS is like the car’s personal climate control—but for the battery. It doesn’t just cool things down when charging heats them up, it also keeps batteries cozy when it’s freezing outside.

Different EVs use different approaches, and each comes with its own strengths and trade-offs:

| Method | How it works | Pros | Cons | Examples |

| Air Cooling | Moves air (natural or forced) across the pack | Simple, low cost, lightweight | Limited cooling capacity, poor in hot climates | Early Nissan Leaf, budget EVs, 2- wheelers |

| Liquid Cooling | Circulates coolant through channels or cold plates | Very effective, uniform cooling, enables fast charging | Adds weight and complexity | Tesla, Tata Nexon EV, Hyundai Kona |

| Refrigerant Cooling | Uses vehicle AC refrigerant directly on battery | Excellent for fast charging and hot climates | Expensive, highly complex | High performance EVs, luxury cars |

| Phase Change Materials (PCM) | Absorbs heat by changing phase (solid to liquid) | Passive, silent, no pumps needed | Limited heat absorption, harder to reset | Research setups, prototypes |

No single method is “best.” It all depends on what the EV is designed for—a small city scooter doesn’t need the same system as a long-range premium car.

Why Good Thermal Management Extends Battery Life

When done right, thermal management helps in ways you can feel as a driver and measure as an engineer:

- Keeps batteries younger for longer: Slows down the invisible chemical wear and tear.

- Maintains range consistency: Your car gives you the miles it promised, winter or summer.

- Enables ultra-fast charging: BTMS protects cells from heat stress when charging at high power.

- Improves safety: Detects and prevents hotspots that could lead to thermal runaway.

- Balances performance: Keeps all cells in sync, preventing one weak link from spoiling the pack.

How Students Can Learn Thermal Management in a Lab

Textbooks talk about temperature effects. But nothing beats seeing the numbers change in real time. That’s why hands-on EV labs are so important.

In an Ecosense EV Lab, for example, students can:

- Charge and discharge a battery under different temperatures in a thermal chamber.

- Log data on capacity fade at 10°C vs 25°C vs 40°C.

- Compare how air cooling vs. liquid cooling affects pack temperature rise.

- Simulate fast charging and watch how BTMS keeps cells within safe limits.

- Analyze thermal runaway scenarios safely in a controlled environment.

These experiments don’t just teach—they spark curiosity. Students begin to see that behind every EV spec sheet is a battle with heat and cold.

Real-World Lessons

The industry has already shown us why BTMS matters:

- Tesla cracked the code with liquid-cooled packs, enabling reliable supercharging.

- Nissan Leaf (earlier models) used air cooling, but owners in hot climates saw rapid degradation.

- Hyundai and BYD now integrate cooling with heat pumps, achieving both energy efficiency and passenger comfort.

Every one of these choices tells a story: thermal design can make or break an EV.

Keep It Cool, Keep It Moving

Battery chemistry often gets the headlines, but temperature control decides the outcome. EV batteries do not just need to be big—they need to be managed.

For students and universities, this opens a powerful teaching moment. By experimenting with thermal systems in the lab, students learn not only how batteries work—but how to make them last, charge faster, and stay safe.

At Ecosense, we believe the future belongs to engineers who know that keeping a battery cool is just as important as making it powerful. That is why our EV Labs include tools for thermal testing, battery cycling, and data analytics—because every great EV story begins with a battery that stays in its comfort zone.