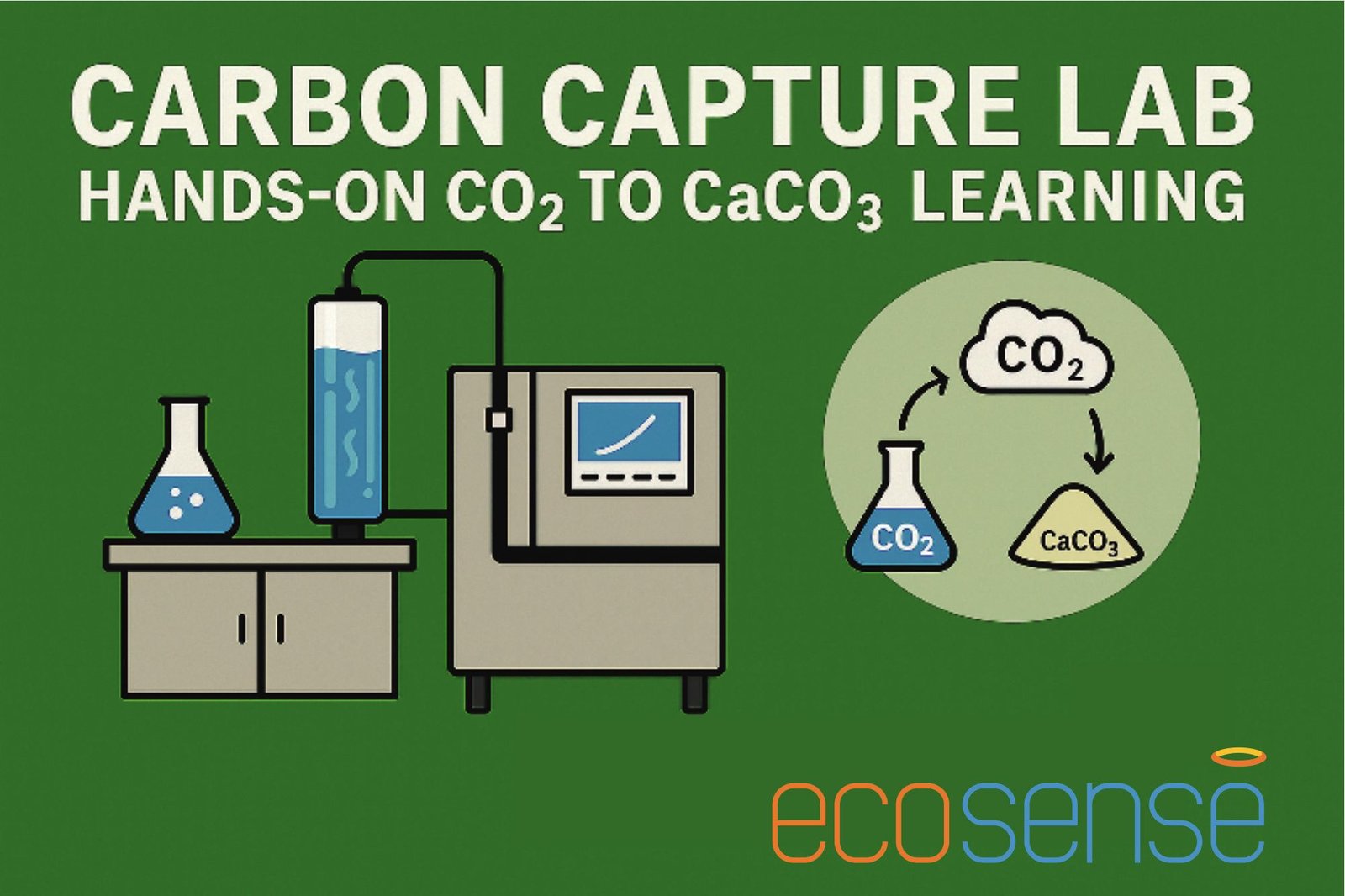

Carbon Capture Lab: Hands-On CO2 to CaCO3 Learning

Carbon dioxide emissions are at the heart of today’s climate challenge. Even with the rapid growth of renewable energy and electric mobility, many industries—such as cement, steel, chemicals, and oil refining—continue to produce unavoidable emissions. To move toward global net zero targets, scientists and engineers are turning to a promising technology known as carbon capture and utilization (CCU).

At its core, Carbon Capture and Storage education requires hands-on exposure to how CO₂ is captured, monitored, and converted before it enters the atmosphere or is stored safely. For universities and research institutions, this field represents both an urgent responsibility and an exciting opportunity. Students who learn the science and engineering behind CCU today will be the ones leading the clean energy transition tomorrow.

Why Carbon Capture Matters

The world emits more than 36 billion tons of CO₂ every year, and cutting these emissions entirely will take time. Renewable energy, hydrogen, and EVs are part of the solution, but they can’t eliminate emissions from heavy industries right away. Carbon capture provides a pathway to reduce emissions from these sectors while other technologies continue to scale.

Unlike many climate solutions that focus only on avoiding emissions, carbon capture directly addresses the carbon already being released. This makes it a critical tool for hard-to-abate sectors, where alternatives are either too expensive or technically unfeasible today.

The Science of Capturing Carbon

Carbon capture is a multi-step process that mimics how industrial plants and research facilities handle gases. It usually begins with a source of CO₂ emissions, such as a power plant’s flue gas. In lab environments, this is simulated using controlled gas mixtures so that students can safely study the process.

The first stage is adsorption, where CO₂ molecules are selectively trapped on a solid material such as zeolites, activated carbon, or more advanced sorbents like metal-organic frameworks (MOFs). Some systems use absorption, in which CO₂ dissolves into a liquid solution, often based on amines. Both approaches are effective, but each comes with different energy and material requirements.

Once the CO₂ is captured, the system must undergo desorption. This step regenerates the sorbent or solvent by releasing the CO₂, usually by applying heat or reducing pressure. The captured CO₂ can then be collected in concentrated form.

The final step in many academic demonstrations is utilization or storage. One of the simplest and most visual examples is mineralization, where CO₂ reacts with calcium hydroxide to form calcium carbonate (CaCO₃), a stable, white solid.

Carbon Capture Technologies in Context

Here’s a side-by-side look at different capture methods, highlighting how they work, their benefits, and their challenges.

| Method | How it Works? | Advantages | Challenges | Applications |

| Absorption | CO₂ dissolves in liquid solvents (amines) | High capture efficiency, industrially proven | Solvent degradation, high energy for regeneration | Flue gas capture in power plants |

| Adsorption | CO₂ sticks to solid surfaces (zeolites, MOFs) | Lower energy needs, regenerable materials | Limited capacity, scaling challenges | Pilot plants, modular units |

| Membranes | Selectively separate CO₂ through membranes | Compact, modular, no regeneration needed | High cost, limited selectivity | Emerging research, small-scale |

| Direct Air Capture (DAC) | Pulls CO₂ directly from ambient air | Works anywhere, offsets diffuse emissions | Low CO₂ concentration makes it energy-heavy | Climate startups, negative emissons projects |

| Mineralization | Reacts CO₂ with minerals to form carbonates | Permanent storage, creates useful products | Needs large mineral inputs, slow kinetics | Cement, Construction Materials |

This comparison helps students see why no single method is "best"-each has a role depending on context.

Why Education and Research Are Critical

While global industries experiment with CCU at scale, universities play an equally important role. Hands-on labs allow students to observe how different technologies perform in controlled conditions, measure efficiency, and analyze data. This kind of learning builds the skills students will need as carbon management specialists, process engineers, or sustainability consultants.

For faculty and researchers, lab-scale CCU platforms provide an opportunity to test new sorbents, optimize regeneration cycles, and explore utilization pathways. These results can contribute to published research, patents, and even industry collaborations.

Examples of Lab Experiments in Carbon Capture

Students can conduct a range of experiments to understand CCU principles. Below are a few examples:

| Experiment | Objective | Student Outcome |

| Sorbent Efficiency Test | Compare zeolites, activated carbon, and MOFs for adsorption performance | Learn about material properties and capture capacity |

| Energy analysis of Desorption | Study energy use at different temperatures and pressures | Understand trade-offs between efficiency and energy cost |

| Mineralization Yield Study | Convert CO₂ into CaCO₃ under varying conditions | Measure utilization potential and product formation |

| Process Control Response | Use PID controls to stabilize capture efficiency | Gain hands-on exposure to automation and system dynamics |