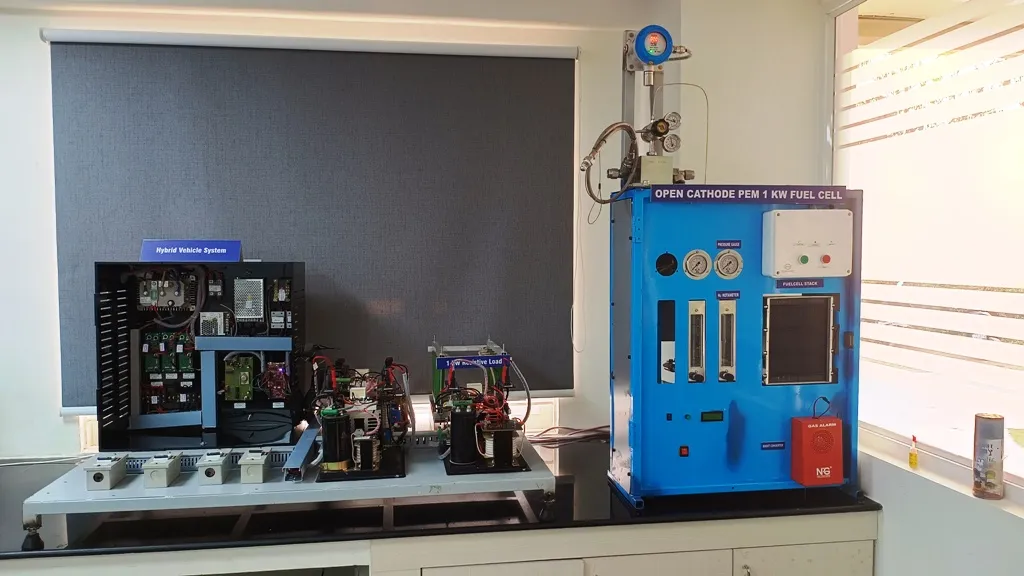

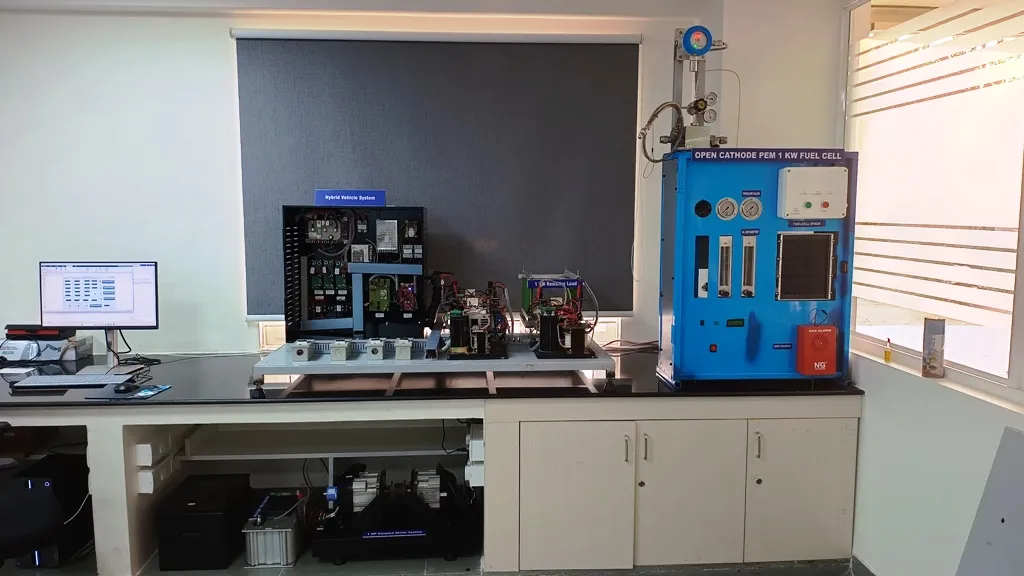

Fuel Cell Drive Train Core

The heart of the system is a fuel cell–based electric drive train configured around a DC bus architecture. The fuel cell acts as the primary energy source, supplying power to a programmable motor controller driving an electric traction motor. The setup allows controlled loading and dynamic operating conditions for detailed analysis.

Key learning focus:

- Fuel cell voltage–current characteristics.

- Power electronics interfacing.

- Motor torque–speed behavior under varying loads.

Regenerative Braking Integration

A major upgrade to the installation is the addition of regenerative braking functionality. During deceleration or braking conditions, the traction motor operates as a generator, converting kinetic energy back into electrical energy.

This recovered energy is routed through the power electronics and managed by the control system, enabling learners to study:

- Energy recovery efficiency

- Impact of regenerative braking on overall system efficiency

- Interaction between fuel cell output and recovered power

- Control strategies for smooth transition between motoring and regeneration

The regenerative braking feature brings the lab closer to real FCEV operating conditions found in modern electric and hydrogen vehicles.