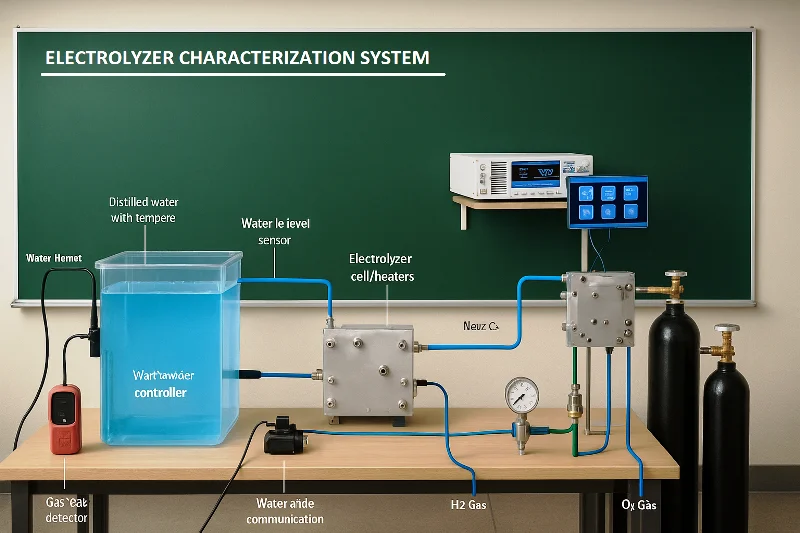

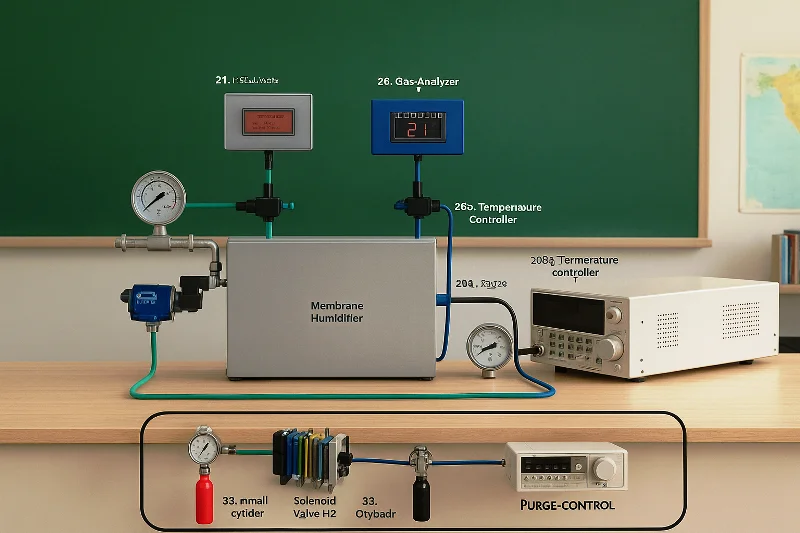

Green Hydrogen Generation, Storage and Utilization System

The Green Hydrogen Generation, Storage and Utilization System is a customizable experimental and research platform designed to facilitate the comprehensive study of the entire green hydrogen cycle. It enables users to explore every stage—from renewable energy integration (via Solar PV arrays or PV emulator systems) and water purification, to hydrogen generation using a choice of electrolyzers (PEM, AEM, or Alkaline), followed by safe storage and final utilization through a PEM fuel cell. This system offers a complete hands-on learning environment, making it ideal for academic institutions, research laboratories, and technology training centers focused on advancing hydrogen energy technologies with a strong focus on safety, control, and performance analysis.