Green Hydrogen Generation and Storage System

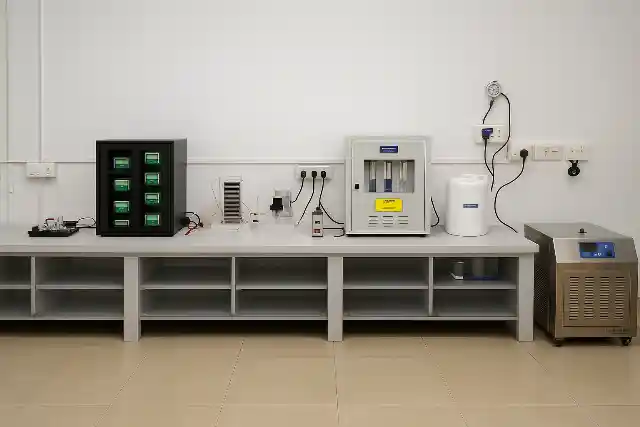

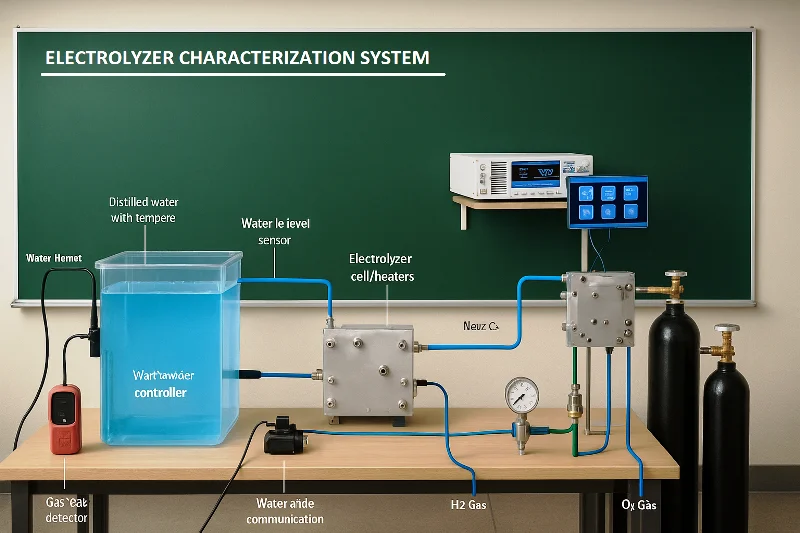

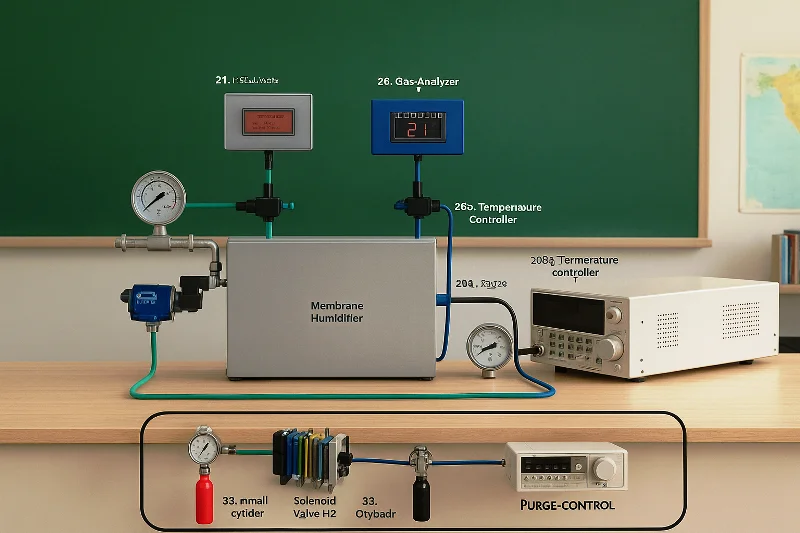

The Green Hydrogen Generation and Storage System by Ecosense is a modular, reconfigurable educational and research-grade platform that replicates the complete hydrogen value chain—from renewable power harvesting to hydrogen generation and safe storage. Designed for engineering institutions, R&D labs, and clean energy centers, this system serves as a real-world replica of decentralized hydrogen production hubs. It enables comparative experimentation with leading electrolyzer technologies (PEM, AEM, Alkaline) and supports multiple input sources including photovoltaic arrays, PV emulators, and AC grid supply. With the flexibility to switch technologies and test variables under controlled lab conditions, this platform prepares students and researchers to design, operate, and optimize hydrogen infrastructure in alignment with future energy systems.