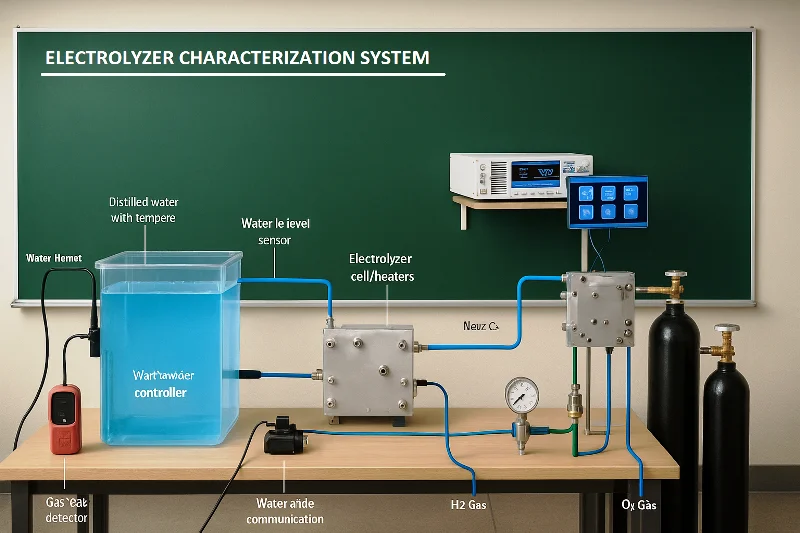

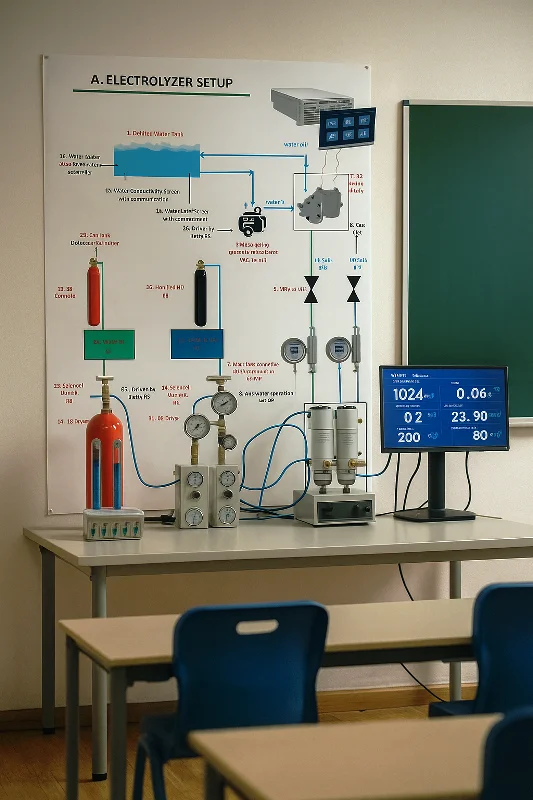

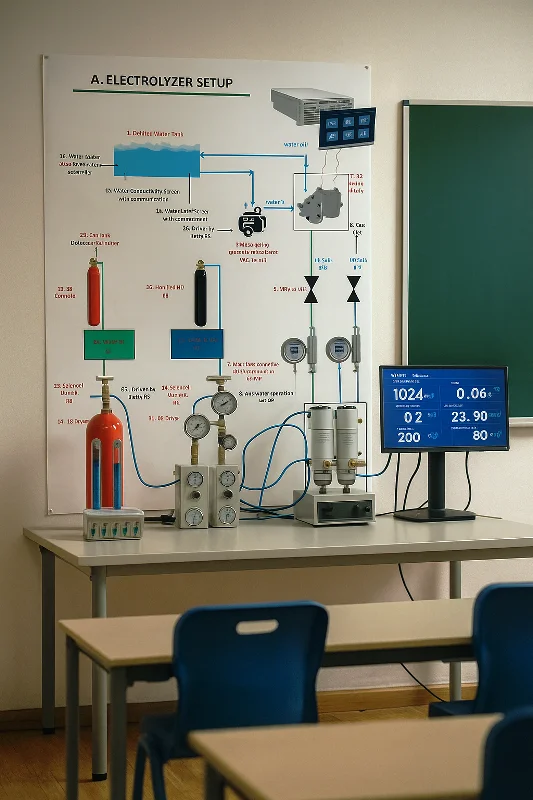

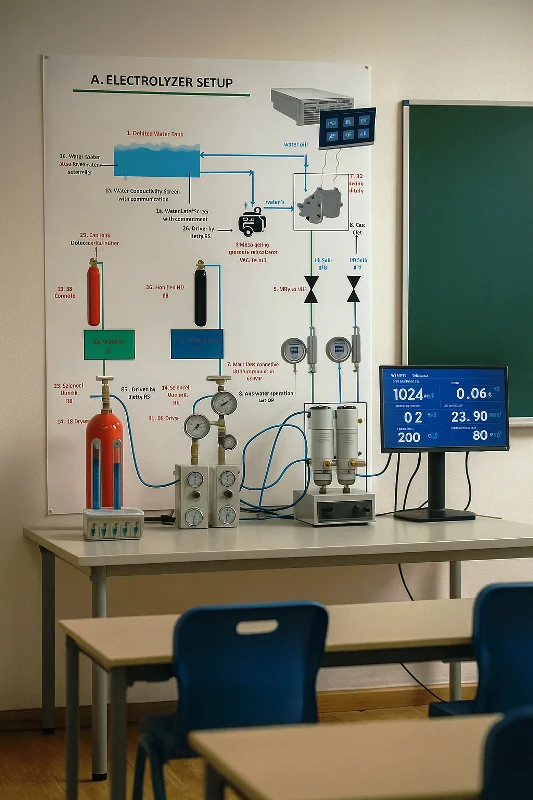

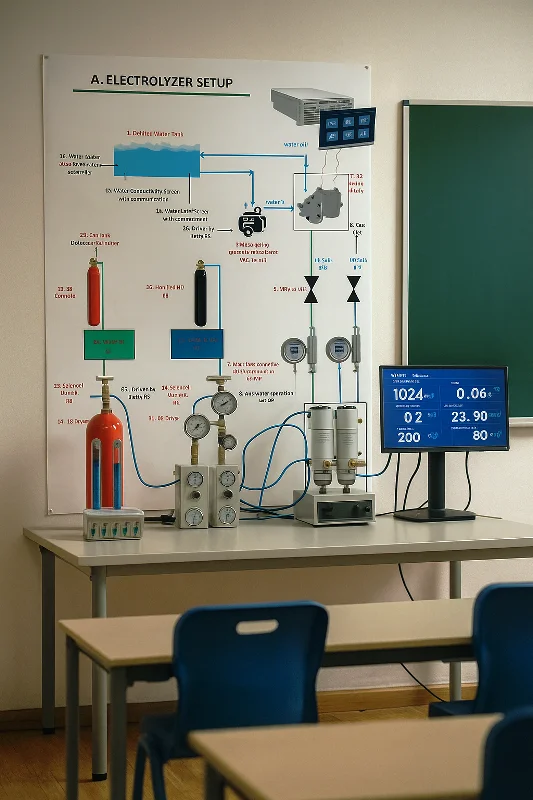

Electrolyzer Characterization System

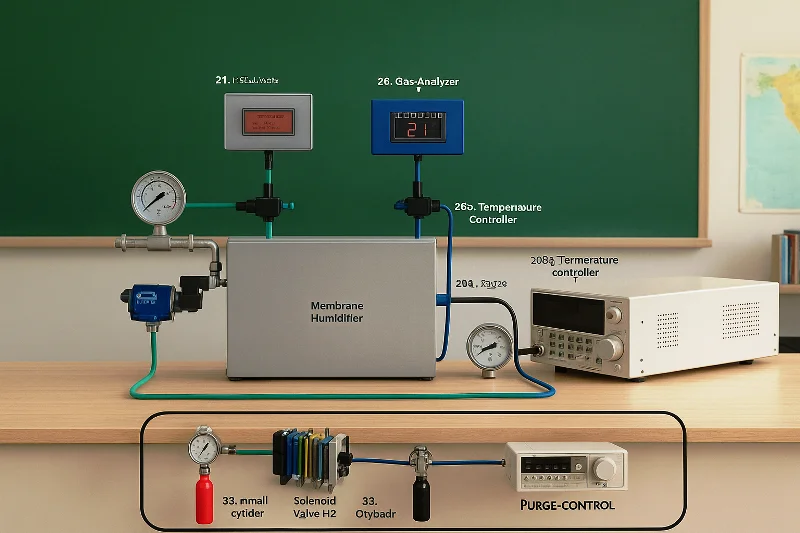

The Electrolyzer Characterization System is a laboratory-grade platform designed for detailed testing and performance evaluation of a hydrogen production electrolyzer based on PEM technology. The system supports experimental studies in green hydrogen generation by enabling controlled investigation of electrochemical behavior, efficiency, and durability under a wide range of operating conditions. It features five stackable PEM cells along with additional variable-area cells, powered by a programmable DC supply to allow precise I–V characterization. A distilled water management unit with conductivity monitoring and peristaltic pumps ensures consistent water quality and flow. Integrated gas handling units—including dryers, separators, and flow meters—enable accurate measurement of hydrogen and oxygen output. Operating parameters such as temperature, pressure, voltage, and flow rate are independently adjustable and monitored through a PC-based control and data logging interface. Comprehensive safety systems make the platform suitable for long-duration testing of electrolyzers for hydrogen production in academic and research laboratories.