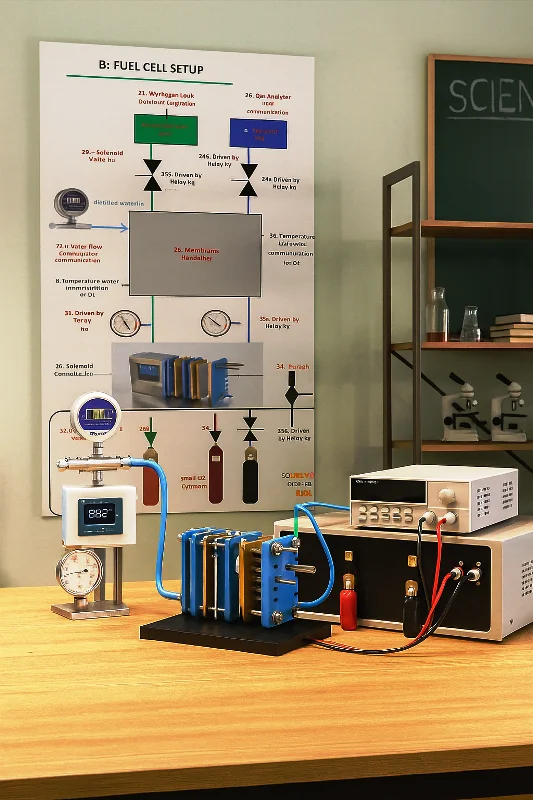

Fuel Cell Characterization System

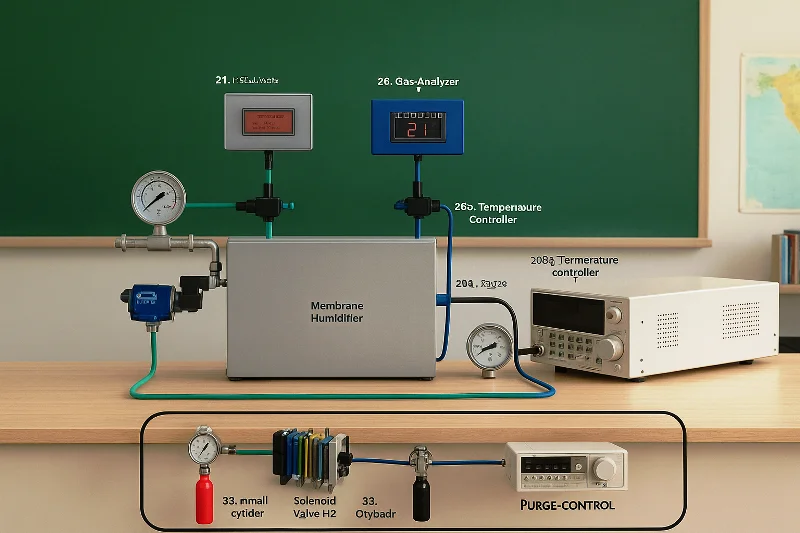

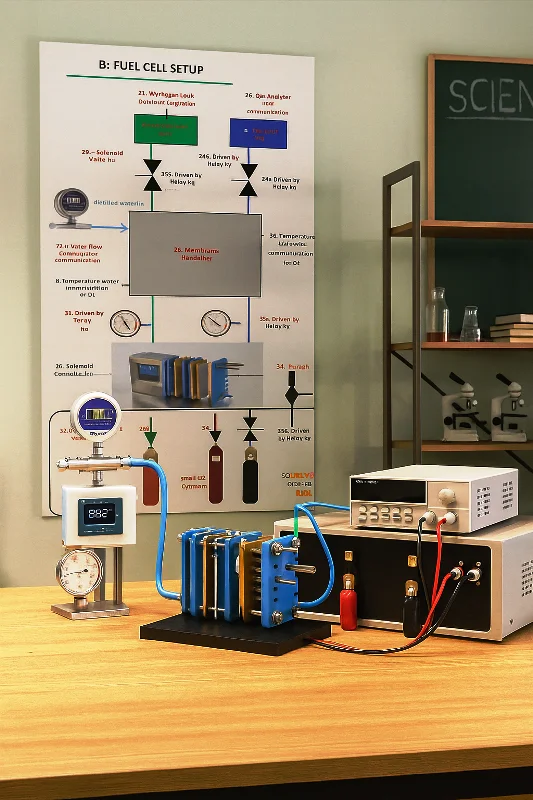

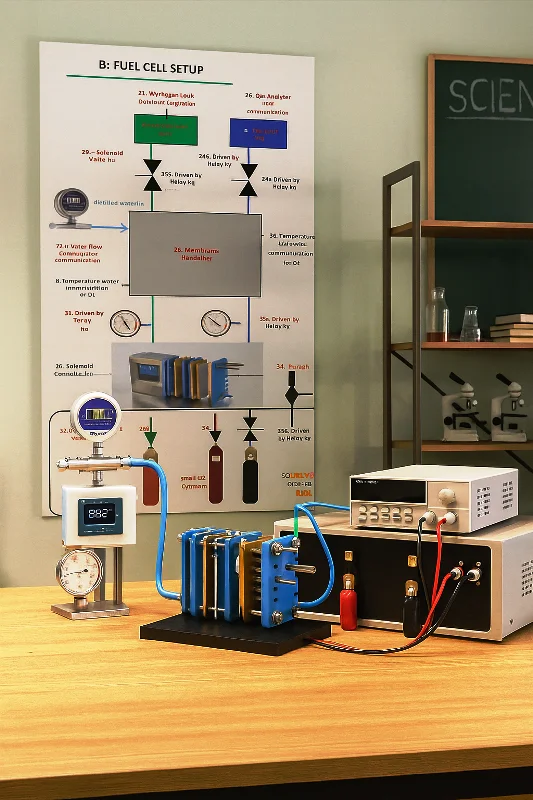

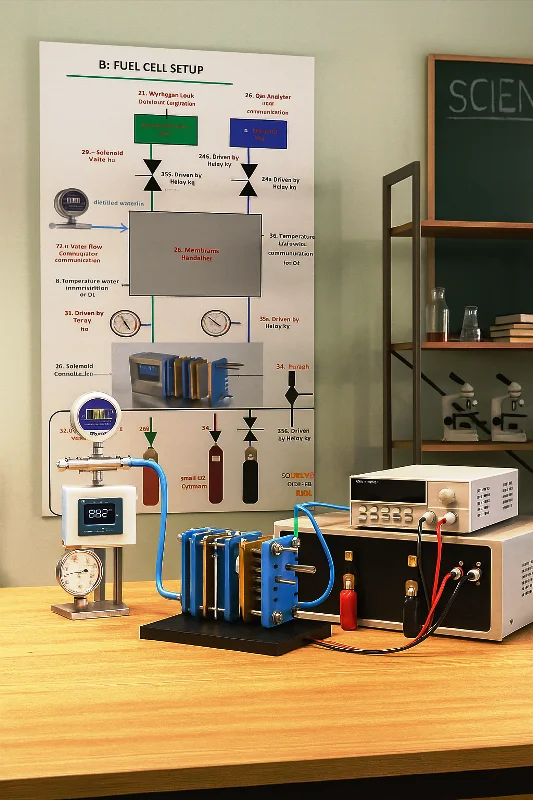

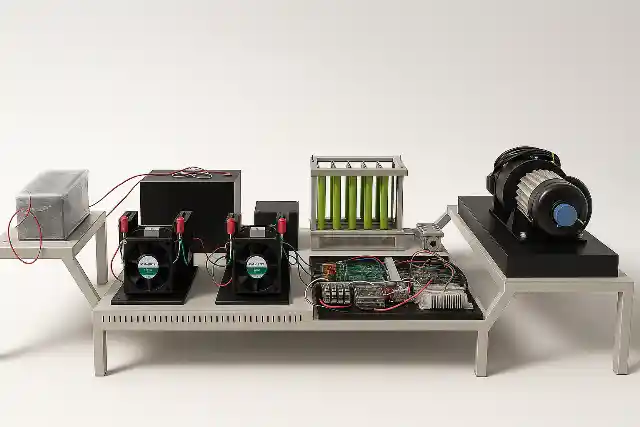

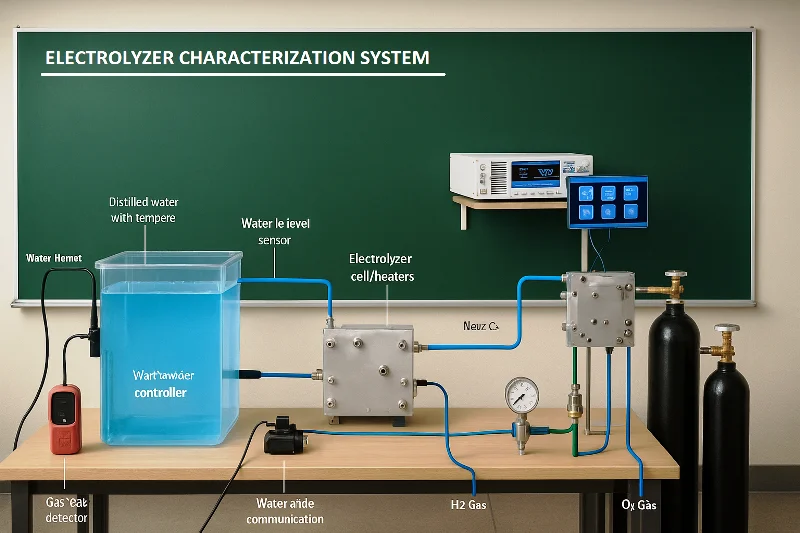

The Fuel Cell Characterization System is an advanced experimentation and research platform for studying PEM fuel cells. It enables detailed exploration of efficiency, durability, and performance under varied operating conditions. The setup includes five single cells and three additional MEA sizes, allowing comparative analysis and scale-up research. Its stackable architecture links single-cell studies to stack-level applications, bridging the gap between laboratory learning and practical deployment. With PC-enabled control, researchers can regulate temperature, humidity, and gas pressure while receiving real-time feedback. A programmable electronic load supports experiments on dynamic operating conditions and optimization. Integrated humidifiers and gas management systems ensure consistent performance. Built-in safety features such as hydrogen leak detection, automatic purging, and overpressure protection guarantee secure operations. Tailored for universities, training centers, and R&D labs, the system provides a complete, safe, and flexible environment for advancing green hydrogen research and innovation.