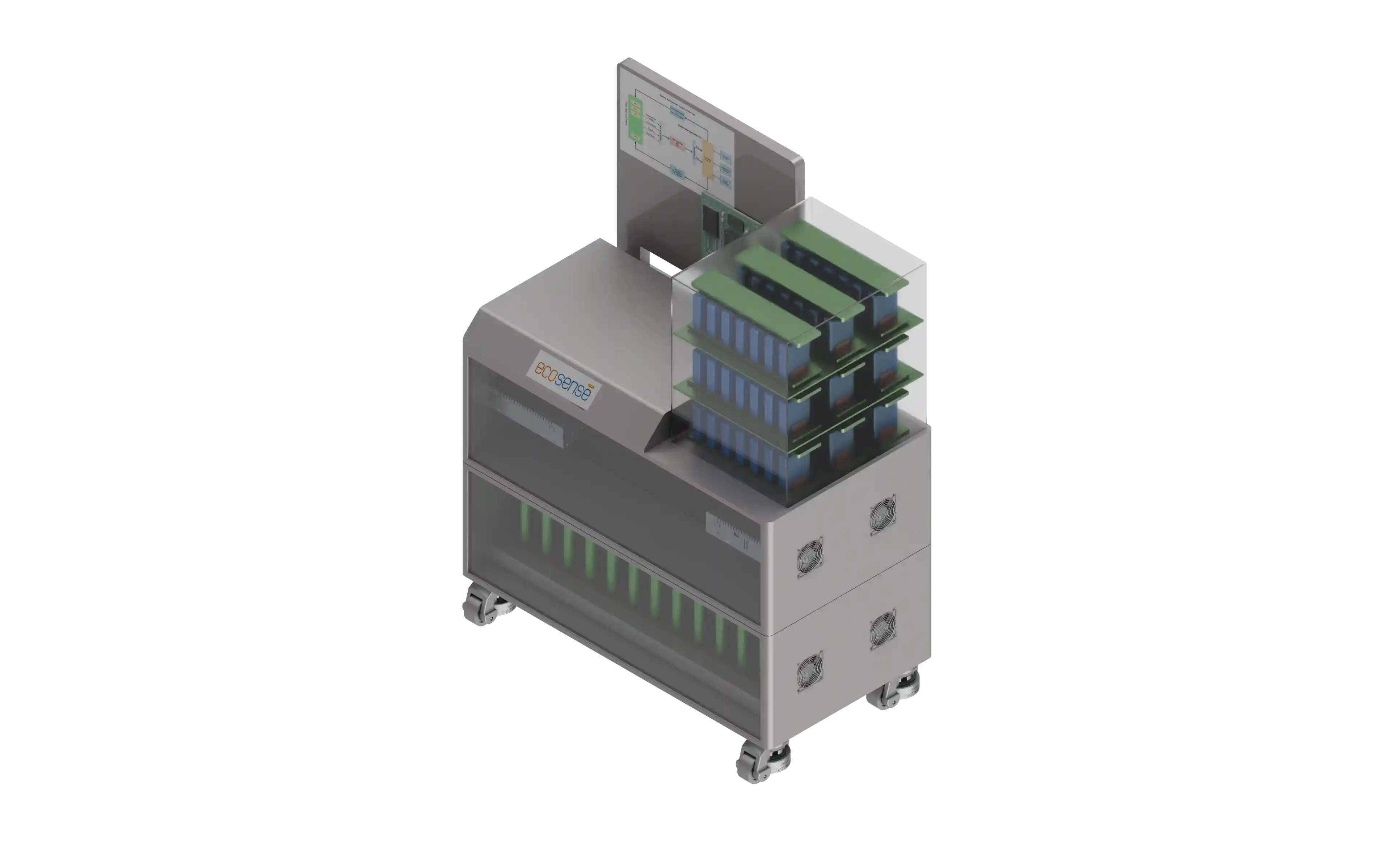

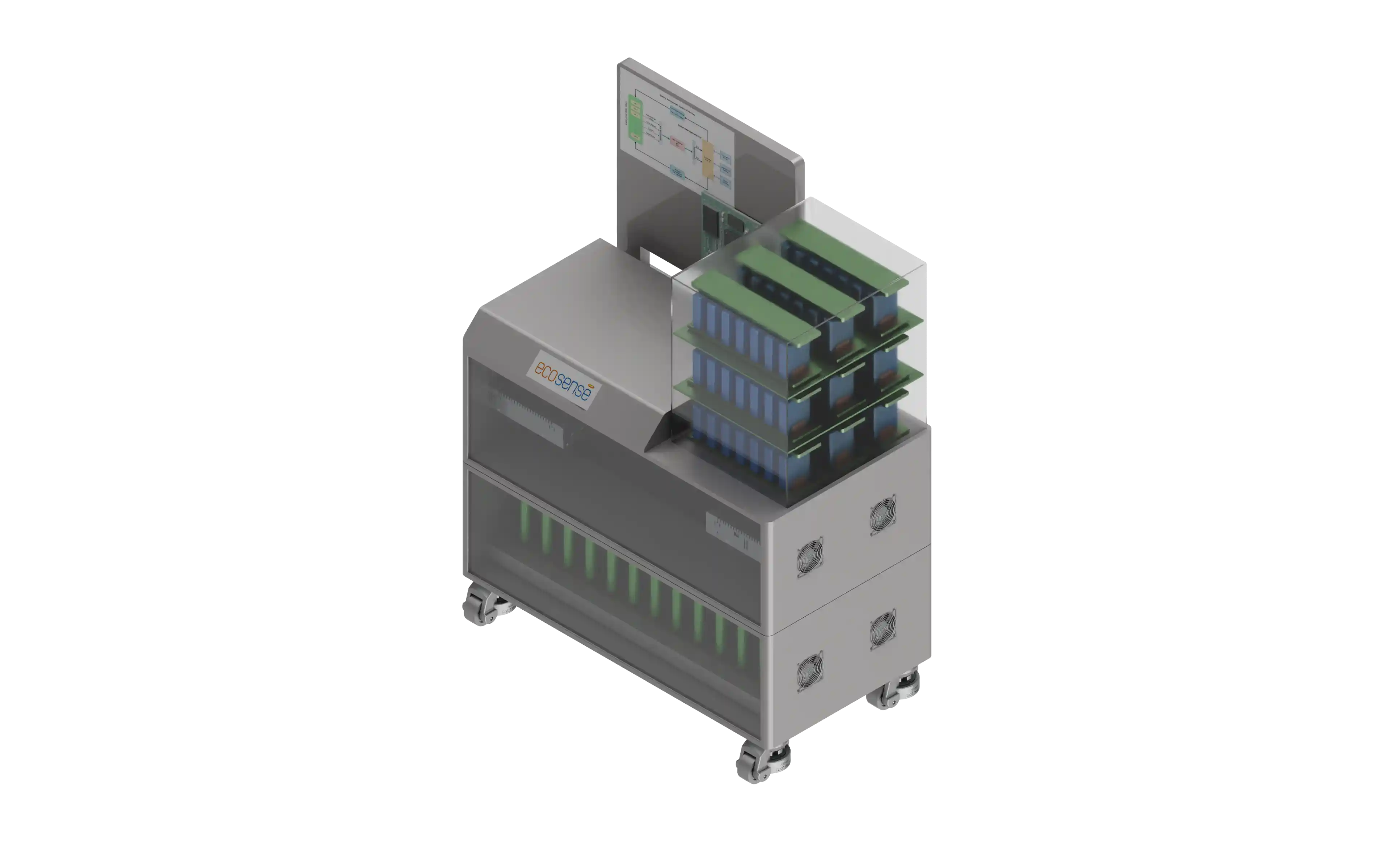

BMS Learn & Build Platform

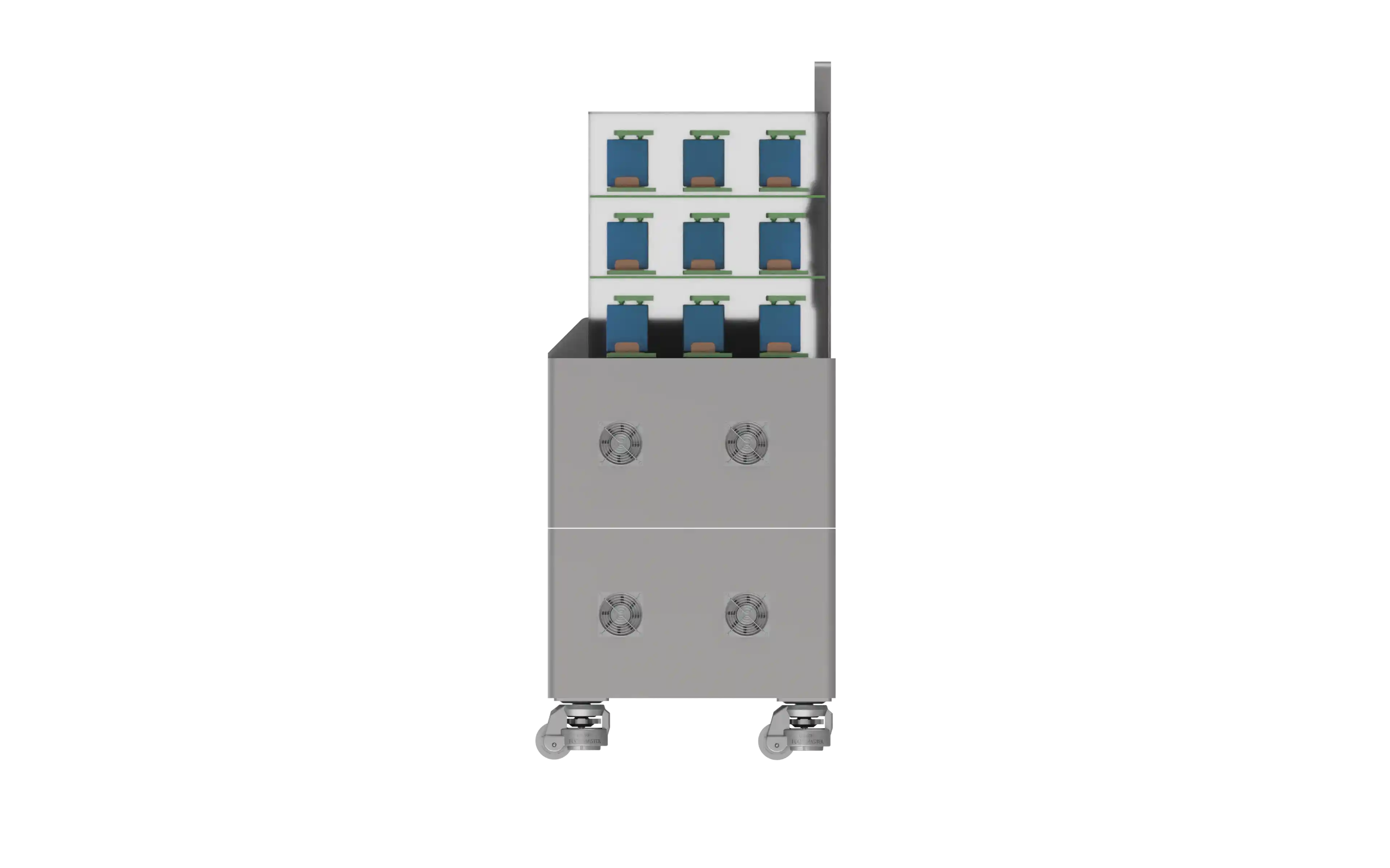

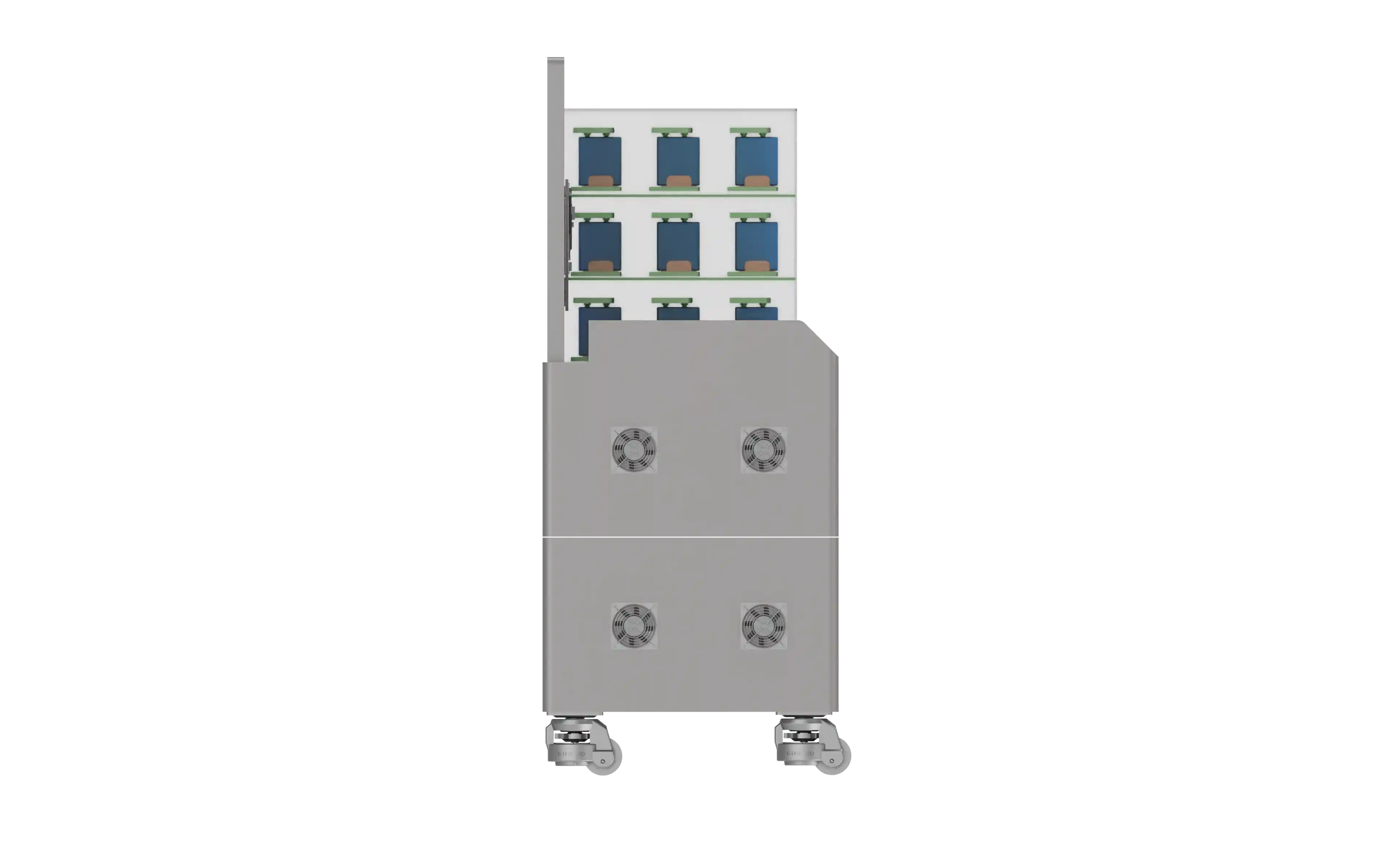

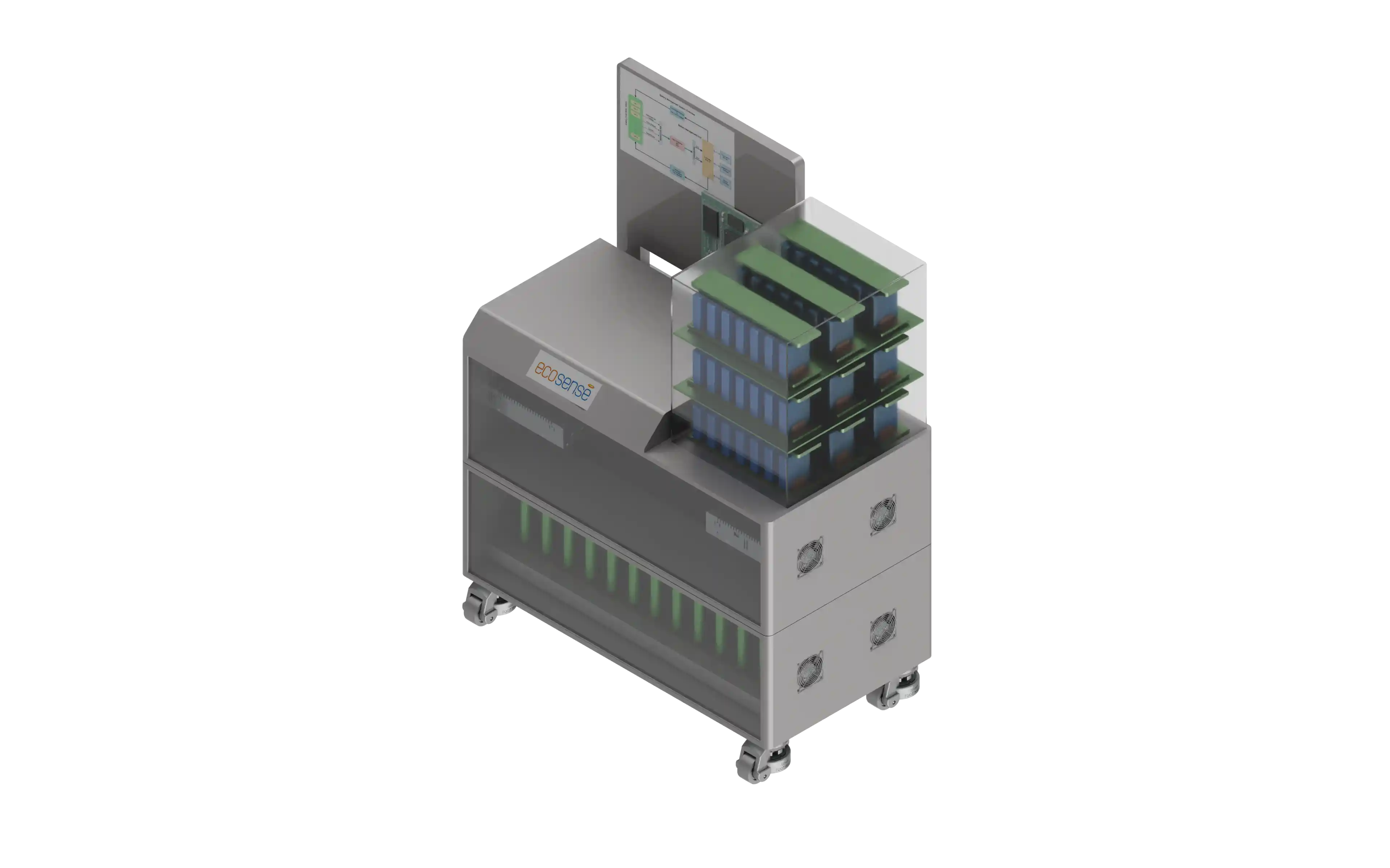

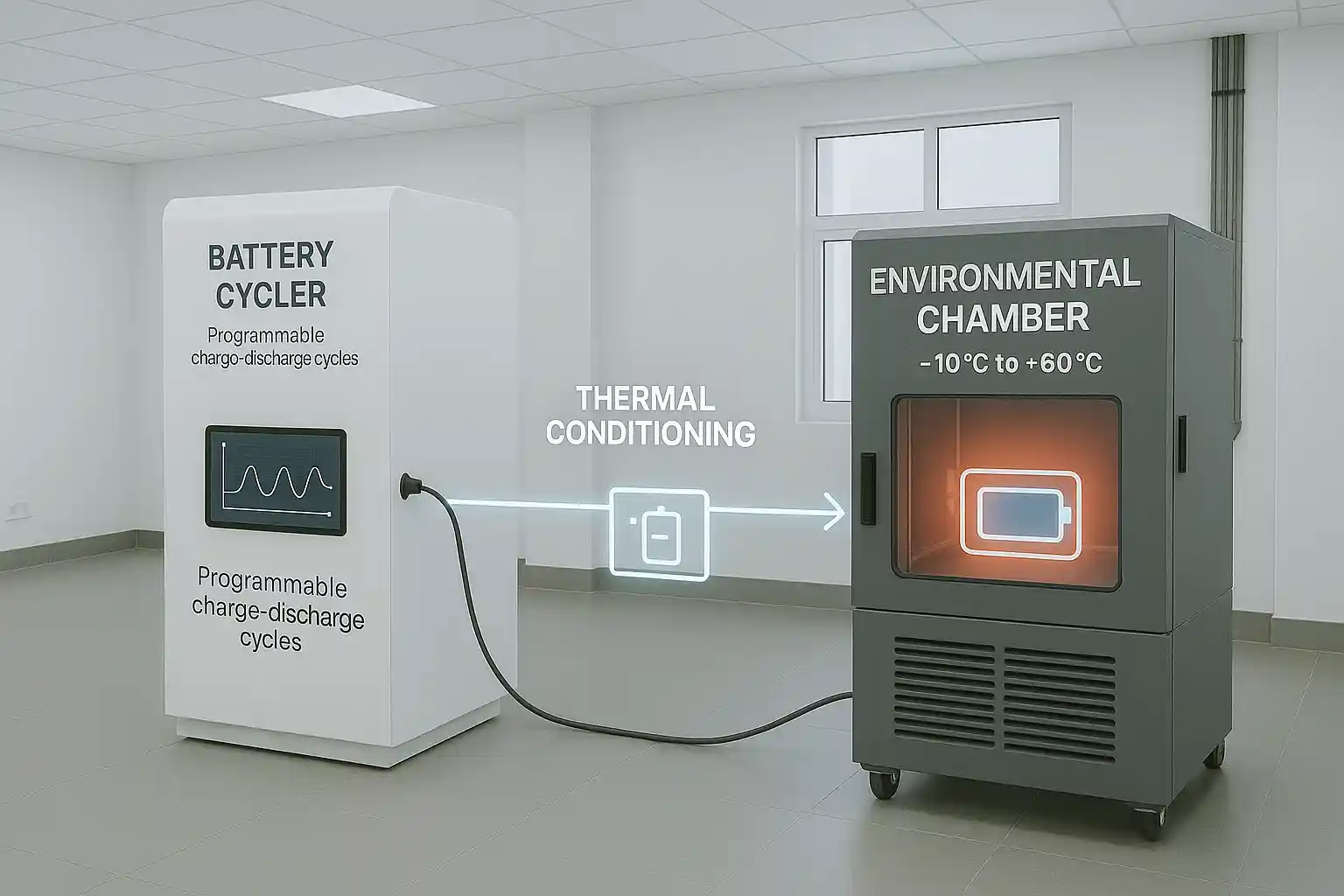

The BMS Learn & Build Platform is a modular training and research system designed to bridge classroom learning with real-world battery applications. It enables students, researchers, and developers to design, program, and validate Battery Management System (BMS) algorithms on real battery packs, addressing the growing demand for safe and intelligent battery management in electric vehicles and energy storage systems.The platform integrates a BMS development unit, a battery cycler with data analytics, and an environmental chamber for controlled charge–discharge and thermal testing. With LabVIEW-based monitoring and open-source firmware, users can configure experiments, simulate protection events, and analyze battery performance in real time. The system provides a scalable, hands-on environment for learning, algorithm development, and BMS validation.