Solar Concentrator Training System

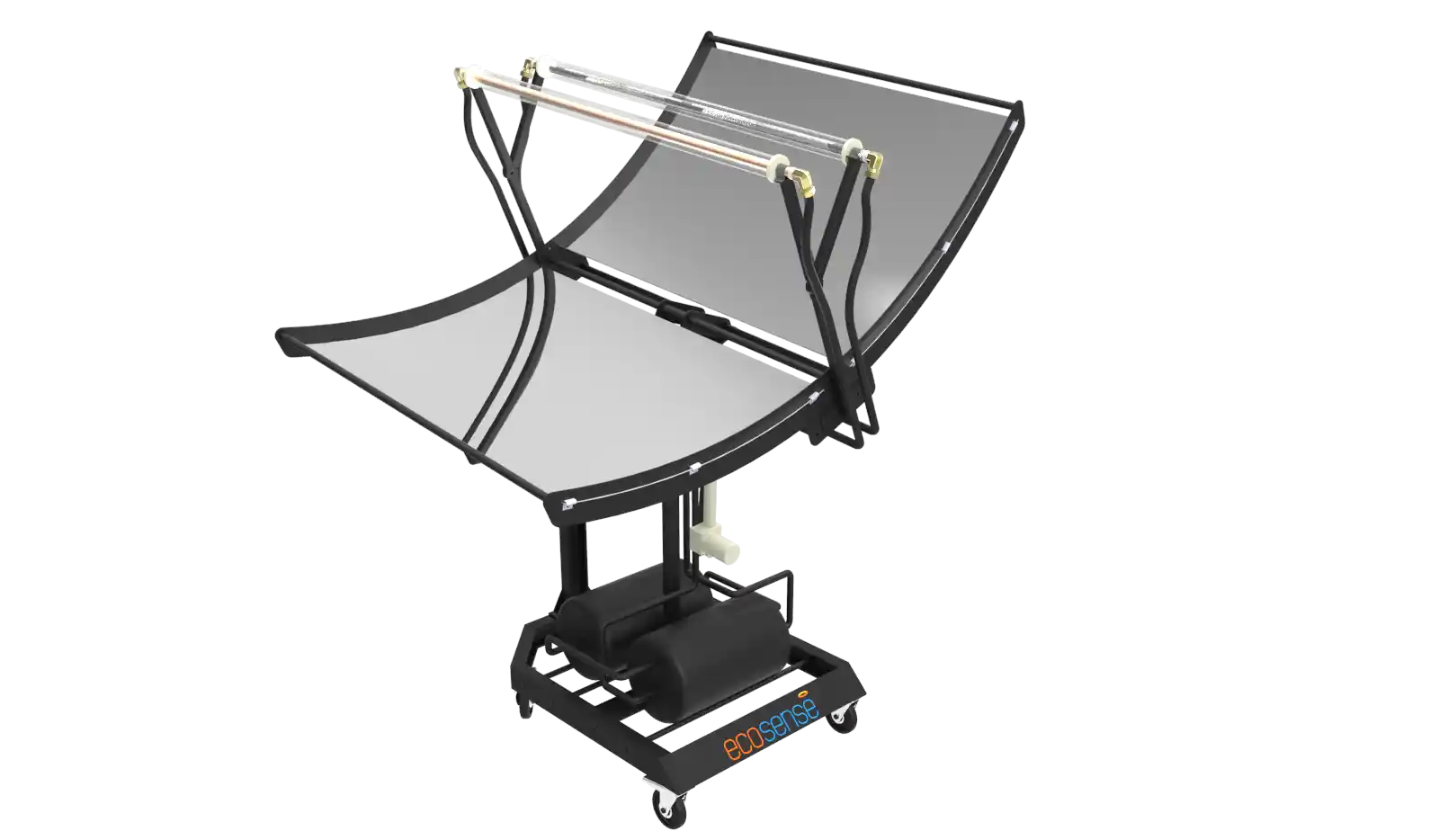

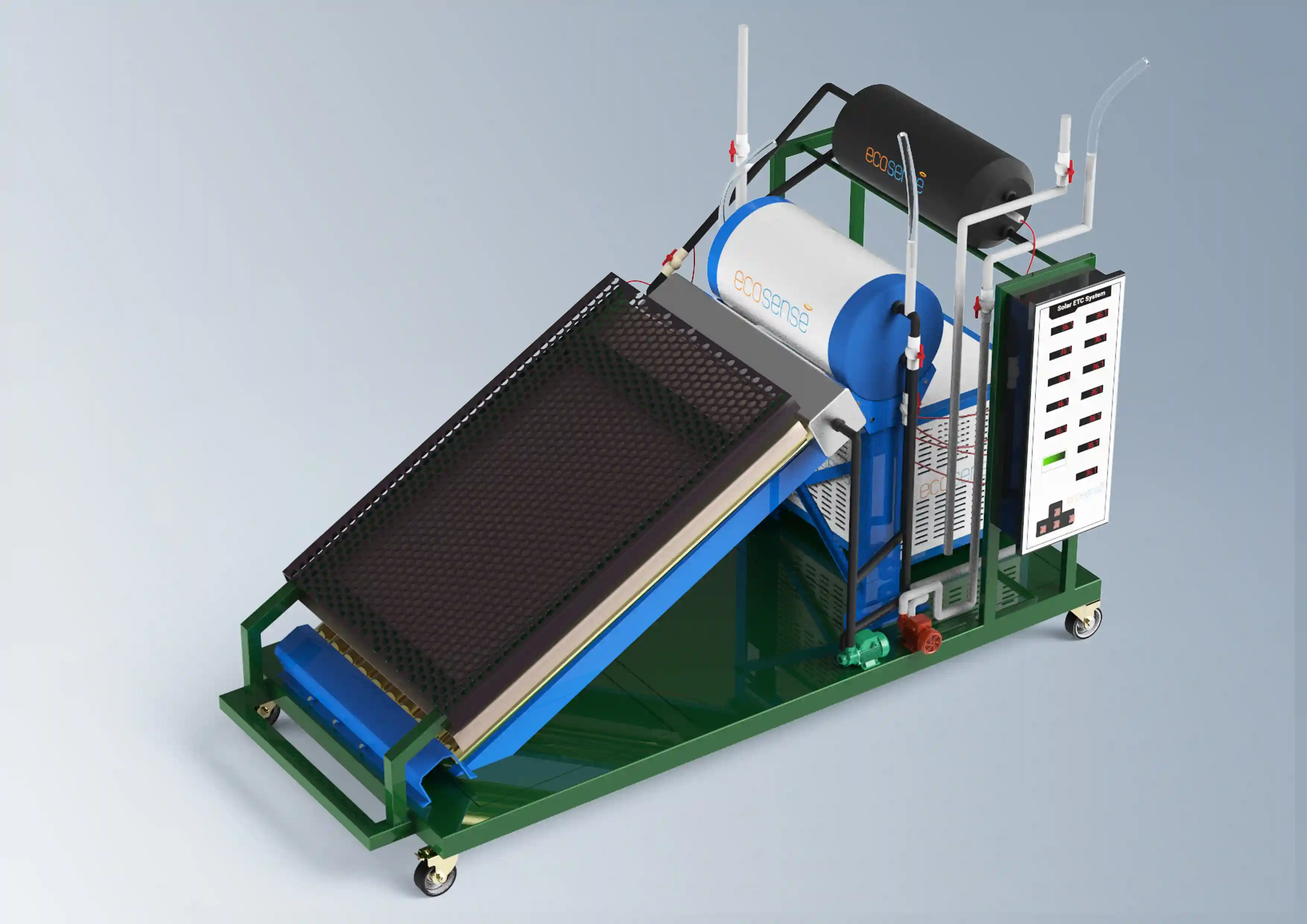

The Solar Concentrator Training System is a compact and modular experimental platform designed to replicate the functionality of a solar parabolic trough collector–based water heating system. This solar power concentrator setup comprises parabolic reflectors, absorber tubes, a sun-tracking mechanism, piping, storage tanks, and a control panel. The system enables hands-on learning and in-depth research in solar thermal technologies using a laboratory-scale solar concentrator configuration. Its adaptability to different working fluids, absorber materials, insulation thicknesses, and storage configurations makes this solar power concentrator system highly suitable for educational institutions and research laboratories studying heat-transfer dynamics and efficiency variations in solar concentrator–based thermal systems under diverse operating conditions.