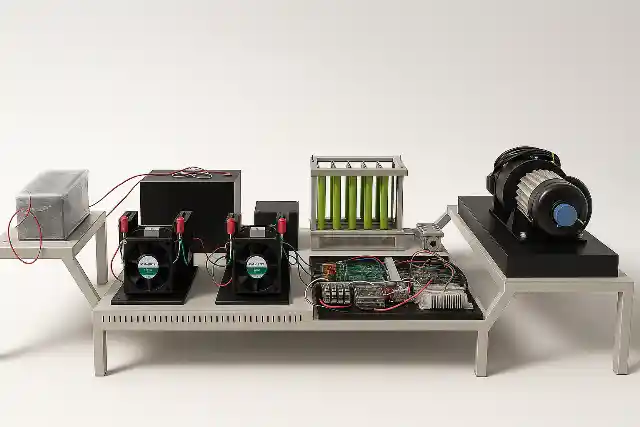

Fuel Cell Training System

The Fuel Cell Training System is a fully integrated, modular, and scalable experimental setup designed to bridge the gap between fuel cell theory and practical application. Built for engineering institutes, research labs, and skill development centers, this lab platform allows users to explore everything from fundamental electrochemistry to advanced energy system integration. With a real PEM fuel cell stack at its core, and support components such as a charge controller, battery bank, inverter, and active load modules, the lab facilitates a wide range of experiments, from V-I curve plotting to hybrid system design. Whether you are a student learning fuel cell basics or a researcher developing advanced MPPT algorithms, the Fuel Cell Training System delivers both flexibility and depth.