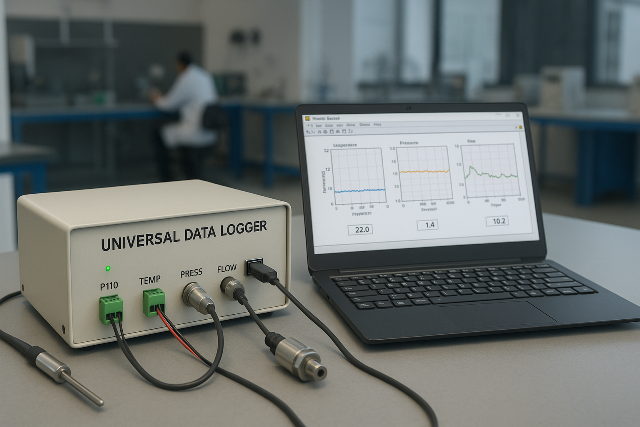

Universal Datalogger

The Universal Data Logger System is a highly adaptable platform designed to acquire, display, and log real-time data from multiple sensor types including temperature (RTDs, thermocouples), pressure, and flow sensors. Ideal for multidisciplinary labs, the system supports a wide range of input types and allows students and researchers to perform comprehensive measurements and data analysis across various energy, fluid, and thermal systems. Its modular design and LabVIEW-based GUI make it perfect for educational institutions and industrial training centers that require accurate, flexible, and scalable data acquisition systems.