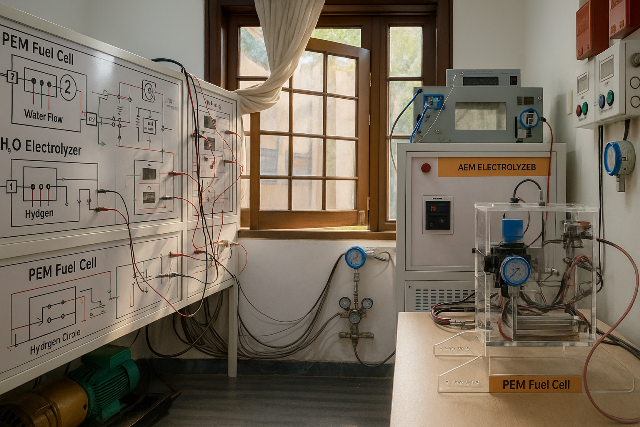

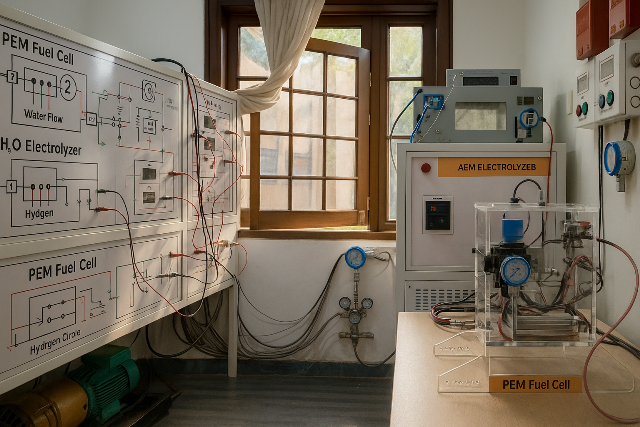

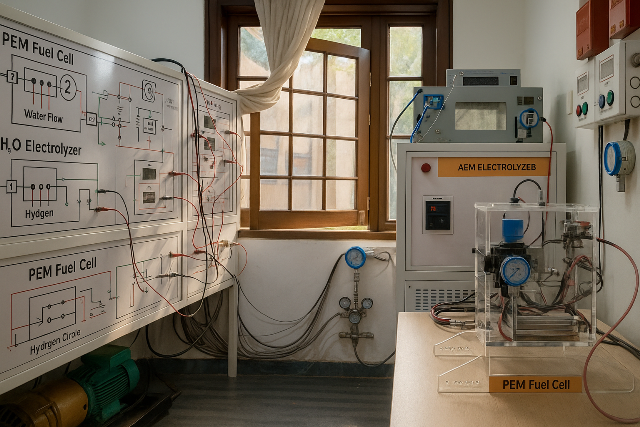

Green Hydrogen Microgrid

The Green Hydrogen Microgrid by Ecosense is a cutting-edge educational and experimental platform designed to demonstrate the generation, storage, and utilization of hydrogen energy integrated within a smart microgrid system. This system enables students and researchers to explore real-time renewable energy integration, green hydrogen production via electrolysis, and electricity generation using fuel cells. It provides a holistic learning experience in advanced energy systems, making it an ideal tool for institutions aiming to lead in hydrogen technology and sustainability.