The thermal energy storage (TES) can be defined as the temporary storage of thermal energy at high or low temperatures. The TES is not a new concept, and at has been used for centuries. Energy storage can reduce the time or rate mismatch between energy supply & demand and it plays an important role in energy conservation. Energy storage improves performance of energy systems by smoothing supply and increasing reliability. For example, storage would improve the performance of a power generating plant by load leveling. The higher efficiency would lead to energy conservation and improve cost effectiveness. Some of the renewable energy sources can only provide energy intermittently. Although the sun provides an abundant, clean and safe source of energy, the supply of this energy is periodic following yearly and diurnal cycles; it is intermittent, often unpredictable and diffused. Its density is low compared with the energy flux densities found in conventional fossil energy devices like coal or oil-fired furnaces. The demand for energy, on the other hand, is also unsteady following yearly and diurnal cycles for both industrial and personal needs. Therefore, the need for the storage of solar energy cannot be avoided.

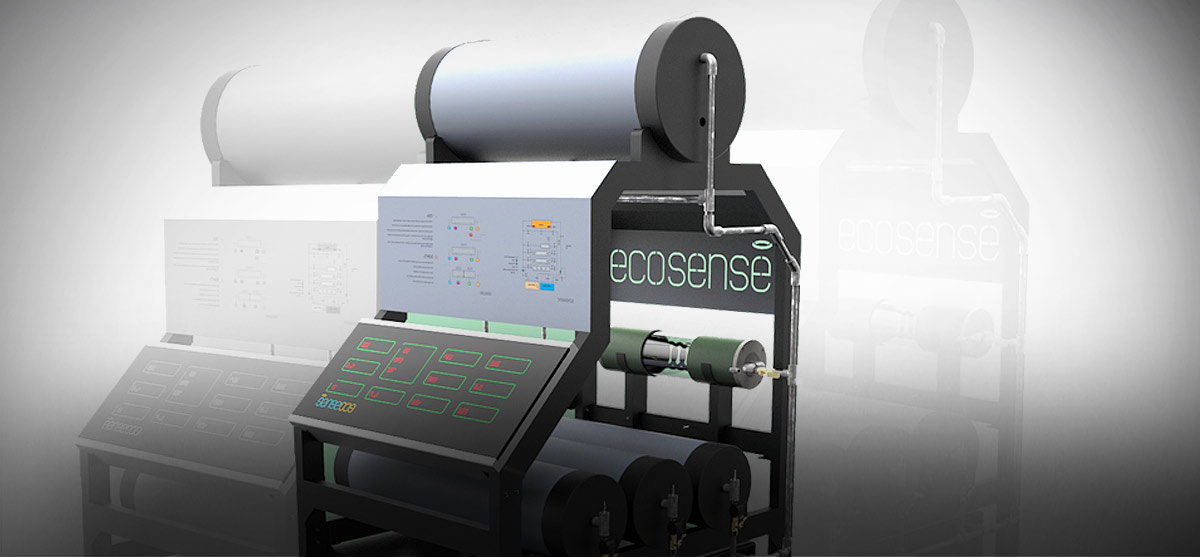

This system has been designed to perform TES related experiment by using PCM materials. As there are several types of PCM, the system has been designed to perform experiment with at least two PCM separately. Provision is also kept to examine the combine (known as cascading) effect of two PCMs in thermal energy storage. To visualize the phase changes in the material another set of arrangement are there in the system.

Technical Characteristics ≫

- Artificial Source of heat

- Simple to integrate with solar thermal devices such as parabolic trough collector

- Inbuilt storage for two PCMs

- Easy to change the storage unit for new PCM

- Provision to perform experiment in cascading of PCMs

- Provision to perform experiment under different operating conditions (temperature, HTF, flow rate)

- Capable to give experimental knowledge of thermal resistance

- Capable to deliver in-depth knowledge about the charging, storing and discharging stages of latent heat thermal energy storage technology

- Evaluation of heat transfer during charging and discharging of PCM

- Evaluation of system thermal efficiency during charging storing and discharging the PCM

- Evaluation of overall system thermal efficiency

- Calculate FOM of the system

- Comparison of some experimentally and theoretically calculated values

Technical Advantages ≫

- System is rigorously tested and can work continuously without switching off

- Require very less space for installation

- Reliable Quality: Basically, no after sales service is required

- System comes with an illustrated experiment manual detailing every wiring connection to be made

- Specifications can be customized as per requirement

- Detailed demonstration and training of system is done during commissioning of the system

Experiments ≫

- Experiment on PCM-1 (paraffin based)

- Experiment on PCM-2 (fatty acid based)

- Experiment on PCM-1 and PCM-2 in series combination (cascading system)

- Experiment on PCM-1 (paraffin based) at different HTF flow rate during charging and discharging

- Experiment on PCM-2 (fatty acid based) at different HTF flow rate during charging and discharging

- Experiment on PCM-1 and PCM-2 in series combination (cascading system) with different HTF flow rate during charging and discharging

- Experiment on PCM-1 (paraffin based) with different HTF temperature during charging

- Experiment on PCM-2 (fatty acid based) at different HTF temperature during charging

- Experiment on PCM-1 and PCM-2 in series combination (cascading system) at different HTF temperature during charging

Research Options ≫

- Performance analysis of paraffin wax based latent heat thermal energy storage systems with different heat exchangers: an experimental study

- Experimental study of a latent heat thermal energy storage system with different types of insulation (PUF, Rockwool and Glass-wool) having Paraffin wax and Organic mixtures in series combination (cascading)

- Experimental study of latent heat thermal energy storage system with multiple PCMs in series combination

- Performance analysis of a Fatty acid based thermal energy storage system with different insulating materials: an experimental study

- Performance behavior of fatty acid based thermal energy storage system with and without aluminum additive: An experimental study

- Experimental analysis of a multiple PCM based LHTES system with three different types of heat exchangers and solar parabolic trough collector as a source of heat

- Experimental study of a small scale solar parabolic trough collector and latent heat thermal energy storage combine system with multiple PCMs in a storing unit

Specifications ≫

| Components | Sub- Components | Specifications |

| Heat generating unit | Insulated tank | |

| Material | SS-304 | |

| Capacity | 50 (L) | |

| Electric heater-rating | 6000 W | |

| Insulated Energy (heat) storing unit | PCM-1 | |

| Name of PCM | Paraffin wax | |

| Melting temperature | 55 (0C) | |

| Heat of fusion | 173(kJ/ kg) | |

| PCM-2 | ||

| Name of PCM | Organic fatty acid | |

| Melting temperature | 67 (0C) | |

| Heat of fusion | 210(kJ/ kg) | |

| Heat exchanger | ||

| Number | 3 | |

| Heat exchanger tube material | Copper | |

| PCM holding pipe (shell) | ||

| Number | 3 | |

| Material | SS-304 | |

| Control unit | Temperature Meters | |

| Temperature Sensors | ||

| Flow meter & Sensor | ||

| Accessories | External tank | |

| Number | 2 | |

| Hot water Pump | ||

| Manual | ||

Thermal Energy Storage Training System

Click on below links to request a quote or email us.

Thermal Energy Storage Training System gives the provision to perform experiments with different PCMs under different operating conditions.

Email Us

Email Us Call Us - +91-11-41323101

Call Us - +91-11-41323101 Download Info

Download Info